Feb . 19, 2025 11:43 Back to list

Durable Zinc Steel Fence

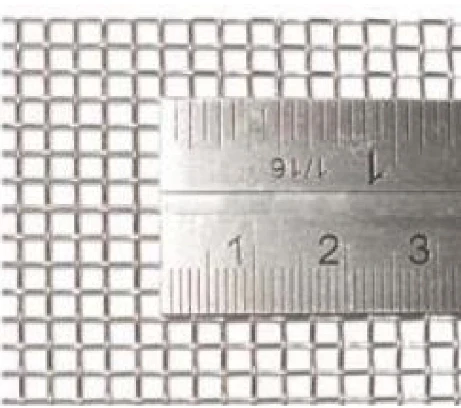

Rebar mesh panels are a staple in the construction industry, but their value extends beyond mere reinforcement. With years of expertise, these panels have proven indispensable in ensuring structural integrity across various building projects. This article delves into the distinct advantages of rebar mesh panels, their applications, and insights from industry experts to help you understand their significance and trust their credibility for your next project.

Trustworthiness in construction materials is non-negotiable. Rebar mesh panels have a proven track record that fosters confidence among users. Their use in critical projects, such as high-rise buildings and public infrastructures, is a testament to their reliability. Professionals depend on them, not just for reinforcement, but as a key element in a structure's enduring success. Beyond the technical advantages, rebar mesh panels offer practical benefits. They streamline construction timelines, reducing labor costs and material waste. By arriving at the construction site ready-to-install, they minimize the need for extensive onsite cutting and bending, mitigating errors and enhancing efficiency. For educational purposes, aspiring engineers and architects can look towards rebar mesh panels as an essential topic within their studies. Understanding their properties, application techniques, and performance under various scenarios equips future professionals with the necessary skill set to address complex structural challenges. When considering rebar mesh panels for your project, it's imperative to source them from reputable suppliers. Experts recommend conducting thorough research or consulting with industry professionals to ensure you're receiving panels that meet the required specifications. Looking for certifications and customer reviews can guide you in making informed decisions. In summary, rebar mesh panels are not just a choice but a cornerstone of modern construction. Their application signifies a commitment to quality, safety, and efficiency—benchmarks that are crucial for building lasting structures. With documented expertise and a robust reputation, these panels will continue to reinforce the future, one grid at a time.

Trustworthiness in construction materials is non-negotiable. Rebar mesh panels have a proven track record that fosters confidence among users. Their use in critical projects, such as high-rise buildings and public infrastructures, is a testament to their reliability. Professionals depend on them, not just for reinforcement, but as a key element in a structure's enduring success. Beyond the technical advantages, rebar mesh panels offer practical benefits. They streamline construction timelines, reducing labor costs and material waste. By arriving at the construction site ready-to-install, they minimize the need for extensive onsite cutting and bending, mitigating errors and enhancing efficiency. For educational purposes, aspiring engineers and architects can look towards rebar mesh panels as an essential topic within their studies. Understanding their properties, application techniques, and performance under various scenarios equips future professionals with the necessary skill set to address complex structural challenges. When considering rebar mesh panels for your project, it's imperative to source them from reputable suppliers. Experts recommend conducting thorough research or consulting with industry professionals to ensure you're receiving panels that meet the required specifications. Looking for certifications and customer reviews can guide you in making informed decisions. In summary, rebar mesh panels are not just a choice but a cornerstone of modern construction. Their application signifies a commitment to quality, safety, and efficiency—benchmarks that are crucial for building lasting structures. With documented expertise and a robust reputation, these panels will continue to reinforce the future, one grid at a time.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.