Dec . 01, 2024 18:30 Back to list

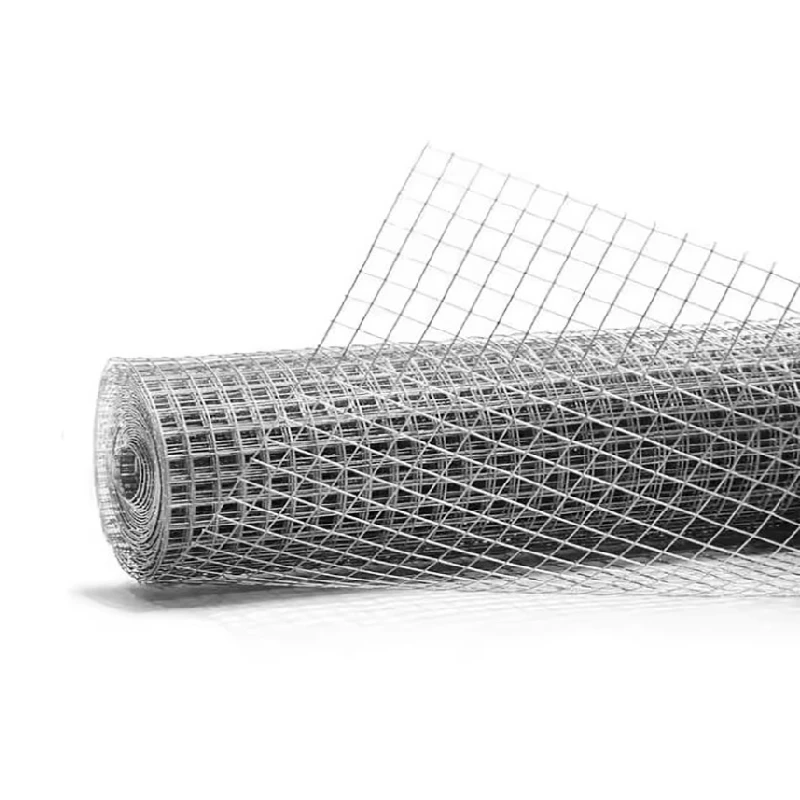

reinforcing mesh

Understanding Reinforcing Mesh A Cornerstone of Modern Construction

Reinforcing mesh, also known as welded wire mesh or reinforcement mesh, plays an essential role in the construction industry. As buildings and infrastructure projects become increasingly complex, the need for durable and robust structural elements has never been greater. In this context, reinforcing mesh provides critical support and enhances the integrity of concrete structures.

At its core, reinforcing mesh consists of a network of steel wires that are welded together at regular intervals. This configuration forms a grid-like structure that can be embedded in concrete to improve its tensile strength. Since concrete is great under compression but weak under tension, incorporating reinforcing mesh helps to bridge this gap, ensuring that structures can withstand various loads and stresses.

One of the primary benefits of using reinforcing mesh is its ability to distribute stresses evenly throughout the concrete. When a structure experiences forces, such as heavy loads or environmental stressors, the mesh helps to transfer these forces across a wider area. This distribution minimizes the risk of cracks and structural failure, thereby prolonging the lifespan of the building or infrastructure.

Reinforcing mesh comes in various shapes and sizes, tailored to specific applications. For instance, different wire diameters and spacing can be selected based on the anticipated load requirements of a project. Additionally, the mesh can be used both in floors, walls, and even precast concrete elements. Its versatility makes it suitable for a wide range of constructions, from residential buildings to large-scale commercial projects.

Another significant advantage of reinforcing mesh is its ease of installation. Rather than placing individual rebar pieces, construction crews can quickly roll out sheets of mesh, which can then be cut to size as needed. This reduces labor costs and construction time while increasing efficiency on-site. It also provides a more uniform distribution of reinforcement, which can be a challenge with traditional rebar placement.

reinforcing mesh

Moreover, the use of reinforcing mesh contributes to sustainability in construction. By optimizing the amount of steel used, projects can minimize their material footprint while ensuring that structures remain robust and safe. This efficient use of resources aligns with modern construction practices aimed at reducing waste and lowering overall costs.

In addition to traditional applications, reinforcing mesh has seen innovative uses in various fields. For example, it has been utilized in the creation of artistic installations, landscaping features, and even furniture design, showcasing its versatility beyond conventional construction. These applications highlight the material’s adaptability and its potential in design-focused projects.

The durability of reinforcing mesh also makes it an ideal choice for structures exposed to extreme environmental conditions, such as coastal buildings that face saltwater corrosion or roadways subjected to freeze-thaw cycles. The resilience of this mesh ensures that it remains effective for years, further enhancing the safety and reliability of the built environment.

As the construction industry continues to evolve, advancements in materials science may lead to the development of even more sophisticated reinforcing mesh options. Innovative coatings and treatments could enhance corrosion resistance, while smart materials might introduce self-healing properties, further elevating the performance of concrete structures.

In conclusion, reinforcing mesh is a fundamental element in modern construction, offering a combination of strength, versatility, and ease of use. Its ability to enhance the durability and safety of concrete structures makes it indispensable in a wide range of projects. As we advance further into an era of sustainable and efficient construction, reinforcing mesh will undoubtedly continue to play a pivotal role in shaping our built environment.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.