Nov . 23, 2024 17:42 Back to list

Enhanced Strength with Reinforced Ribbed Mesh Structures for Construction Applications

The Importance and Applications of Reinforcing Ribbed Mesh in Construction

Reinforcing ribbed mesh, often referred to in the industry as welded wire mesh or ribbed steel mesh, plays a crucial role in modern construction and engineering. This innovative material offers a multitude of benefits that enhance the structural integrity, durability, and efficiency of a wide range of building applications.

Understanding Reinforcing Ribbed Mesh

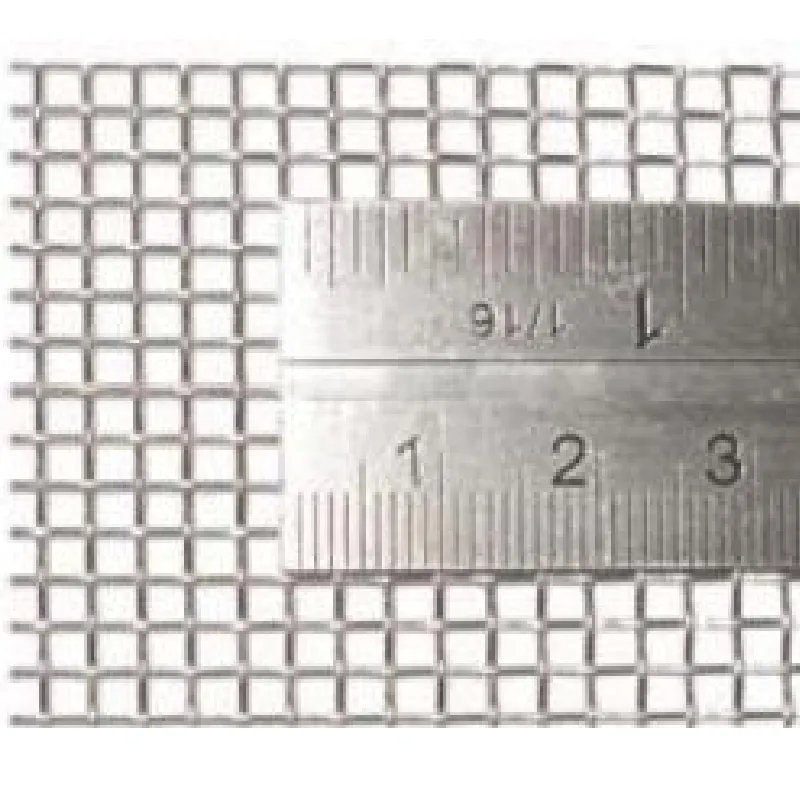

Reinforcing ribbed mesh is made from high-quality steel wires that are welded together in a grid-like pattern. The ribbed aspect refers to the textured surface of the wires, which improves the bond between the mesh and the concrete. This bonding capability is essential because it allows the mesh to effectively distribute tensile forces, which helps prevent cracking and ensures the longevity of concrete structures.

The ribbing on the surface of the wires provides added grip for the concrete, allowing for a stronger, more cohesive structure. Unlike plain wire mesh, ribbed mesh enhances the structural performance by increasing resistance to mechanical strain and load movement. This is particularly important in scenarios where dynamic loads are expected, such as in floors, walls, and pavements.

Applications in Construction

The versatility of reinforcing ribbed mesh makes it suitable for a variety of construction applications

. Here are several key areas where this material is commonly used1. Concrete Slabs Reinforcing ribbed mesh is extensively used in the construction of concrete slabs, including those found in buildings, parking structures, and industrial facilities. The mesh provides a framework that supports the slab, preventing cracking and increasing load-bearing capacity.

2. Foundations In foundation work, ribbed mesh is utilized to enhance the strength of the concrete, particularly in areas subject to heavy loads. By embedding the mesh in the concrete, builders ensure that the foundations can withstand stress and maintain stability over time.

reinforcing ribbed mesh

3. Walls and Facades Ribbed mesh is also applied in precast concrete panels and wall systems. The reinforcement helps maintain the integrity of the walls during construction and over the lifespan of the building, reducing the likelihood of structural failures.

4. Roads and Pavements In road construction, ribbed mesh reinforces concrete pavements, providing increased durability and resistance to cracking. This is especially beneficial in high-traffic areas where pavement integrity is frequently tested.

5. Industrial Structures For industrial applications, such as warehouses and factories, ribbed mesh provides the necessary support for heavy equipment and storage systems. The robustness of the mesh allows for the safe operation of large machinery without compromising structural safety.

Benefits of Using Ribbed Mesh

The advantages of incorporating reinforcing ribbed mesh into construction projects are numerous. Firstly, the material enhances the overall strength and stability of concrete structures, thus extending their lifespan. This durability translates into lower maintenance costs over time, making projects more economically viable in the long run.

Secondly, ribbed mesh improves the efficiency of construction processes. It can be fabricated off-site and delivered ready for installation, significantly reducing the time and labor required on-site. This efficiency is particularly beneficial in fast-paced construction environments where meeting deadlines is crucial.

Moreover, using ribbed mesh can contribute to sustainability efforts. By reinforcing concrete, builders can optimize material usage and reduce waste, as thinner sections can often achieve the same structural performance as thicker ones. This leads to less concrete being required, which is beneficial not only for resource conservation but also for reducing the carbon footprint of construction activities.

Conclusion

In conclusion, reinforcing ribbed mesh is an indispensable component in modern construction. Its ability to enhance the strength, durability, and efficiency of concrete structures makes it a preferred choice for engineers and builders across various applications. As the construction industry continues to evolve, the role of innovative materials like ribbed mesh will be integral to meeting the demands of safety, sustainability, and performance in building projects worldwide. By understanding and utilizing the advantages of reinforcing ribbed mesh, the industry can pave the way for more resilient and enduring infrastructures.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.