Feb . 19, 2025 08:14 Back to list

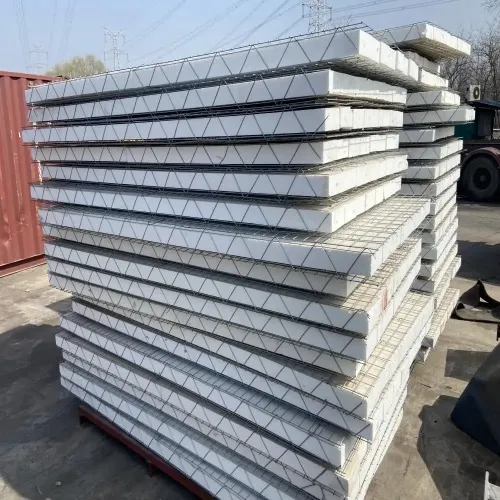

screed mesh

Screed mesh has become an indispensable component in modern construction projects, especially when it comes to creating robust, crack-resistant floors. With years of experience in the construction industry, it’s evident how crucial the role of quality screed mesh is to ensure durability and longevity in building projects.

When addressing the topic of authority in the context of screed mesh, it's essential to rely on reputable sources and manufacturers with a proven track record of quality and reliability. Utilizing industry-certified products ensures compliance with necessary safety and efficiency standards. In addition, consulting with experienced engineers or material experts can provide valuable insights into the selection and application of the right mesh solution for specific project requirements. Trustworthiness in screed mesh usage is built through continuous testing and adherence to established engineering principles. Consistent quality control checks during the manufacturing process guarantee that each piece of mesh fulfills the expected mechanical and chemical properties. Implementing such rigorous standards reassures stakeholders of the material's ability to perform as intended throughout the building's lifecycle. Construction project managers and site engineers often rely on detailed peer-reviewed studies and case histories to substantiate the benefits of screed mesh applications. Documented examples where screed mesh prevented structural failures or greatly increased the lifespan of floor systems lend credibility to its use. Sharing these real-world success stories further solidifies the mesh's role as a valued component in quality construction practices. In conclusion, for those in the construction industry seeking to enhance the durability and strength of their flooring solutions, screed mesh is an essential consideration. Armed with expert knowledge, experience, and a commitment to quality, professionals can select and implement the right screed mesh that not only meets the project's needs but also stands the test of time, ensuring a secure investment in building infrastructure.

When addressing the topic of authority in the context of screed mesh, it's essential to rely on reputable sources and manufacturers with a proven track record of quality and reliability. Utilizing industry-certified products ensures compliance with necessary safety and efficiency standards. In addition, consulting with experienced engineers or material experts can provide valuable insights into the selection and application of the right mesh solution for specific project requirements. Trustworthiness in screed mesh usage is built through continuous testing and adherence to established engineering principles. Consistent quality control checks during the manufacturing process guarantee that each piece of mesh fulfills the expected mechanical and chemical properties. Implementing such rigorous standards reassures stakeholders of the material's ability to perform as intended throughout the building's lifecycle. Construction project managers and site engineers often rely on detailed peer-reviewed studies and case histories to substantiate the benefits of screed mesh applications. Documented examples where screed mesh prevented structural failures or greatly increased the lifespan of floor systems lend credibility to its use. Sharing these real-world success stories further solidifies the mesh's role as a valued component in quality construction practices. In conclusion, for those in the construction industry seeking to enhance the durability and strength of their flooring solutions, screed mesh is an essential consideration. Armed with expert knowledge, experience, and a commitment to quality, professionals can select and implement the right screed mesh that not only meets the project's needs but also stands the test of time, ensuring a secure investment in building infrastructure.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.