Dec . 03, 2024 17:37 Back to list

typical wire mesh for concrete slab

Typical Wire Mesh for Concrete Slabs Understanding Its Importance and Usage

Concrete is one of the most widely used construction materials around the world, thanks to its strength, versatility, and durability. However, the structural integrity of concrete slabs depends greatly on reinforcement methods. One of the most common reinforcement techniques involves the use of wire mesh, also known as welded wire fabric (WWF). Understanding typical wire mesh for concrete slabs is essential for both professional contractors and DIY enthusiasts aiming to achieve optimal results in their projects.

What is Wire Mesh?

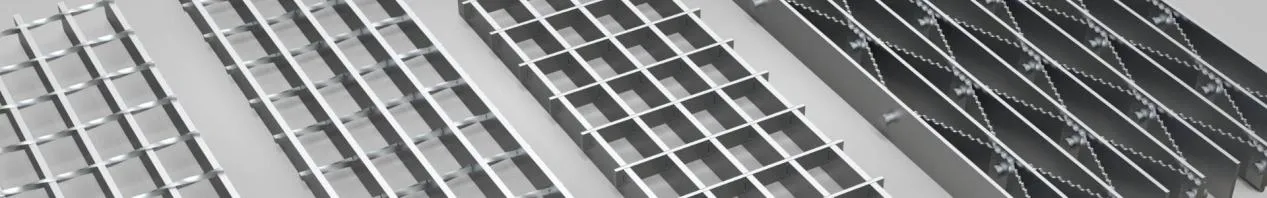

Wire mesh is made from steel wires that are welded together at regular intervals, creating a grid-like structure. This mesh is available in varying sizes, diameters, and configurations, offering a wide range of options to meet specific project requirements. The primary purpose of wire mesh in concrete slabs is to enhance the tensile strength of the slab, as concrete itself is strong in compression but weak in tension. By integrating wire mesh, you can reduce the risk of cracking and improve the overall durability of the slab.

Types of Wire Mesh

When selecting wire mesh for a concrete slab, it is crucial to understand the available types. Common types include

1. Welded Wire Fabric (WWF) As the most frequently used type, WWF consists of longitudinal and transverse wires that are welded together, forming a series of squares or rectangular openings. This type can be used for everything from driveways to floors.

2. Gabion Mesh Although it’s primarily used for erosion control and landscaping projects, gabion mesh can be employed in concrete applications. It consists of hexagonal wire mesh, which can hold stones or gravel for added stability.

3. Expanded Metal Mesh This type of mesh is created by cutting and stretching metal sheets, forming a mesh with a diamond pattern. It provides excellent support and is often used in lighter concrete applications.

Mesh Size and Gauge

typical wire mesh for concrete slab

The size of the mesh openings and the thickness (gauge) of the wire are important factors that influence the performance of the mesh. Commonly, wire mesh for concrete slabs features openings of 6 inches by 6 inches, using wire diameters ranging from 10 to 6 gauge. The choice of size and gauge depends on the specific application and the load the concrete slab is expected to bear. For heavier applications, using a smaller mesh size and thicker wire is advisable.

Placement and Installation

For effective reinforcement using wire mesh, proper placement is critical. The mesh should be placed at the midpoint of the concrete slab's thickness to provide effective tensile support. It’s essential to elevate the mesh above the ground, using chairs or spacers, to ensure it does not sink during the pouring of concrete. Ensuring thorough embedding of the mesh within the concrete is vital for maximizing its benefits and preventing movement.

Benefits of Using Wire Mesh in Concrete Slabs

1. Crack Resistance By distributing stresses uniformly throughout the slab, wire mesh helps prevent cracking caused by shrinkage or external loads.

2. Enhanced Load-Bearing Capacity The addition of wire mesh improves the overall load-bearing capacity of concrete slabs, making them suitable for high-traffic areas.

3. Durability Wire mesh support enhances the lifespan of the slab, reducing the need for maintenance and repairs over time.

4. Cost-Effective Investing in wire mesh can save money in the long run by decreasing the likelihood of structural issues and the associated repair costs.

Conclusion

In summary, typical wire mesh for concrete slabs plays a crucial role in reinforcing and enhancing the performance of concrete structures. With various types, sizes, and application methods available, understanding wire mesh is essential for achieving the best results in concrete construction. Whether you’re a professional contractor or an enthusiastic DIYer, incorporating wire mesh into your concrete projects is a smart decision that can yield long-lasting and durable results. By ensuring proper placement and selection of the right type of mesh, you can enjoy the myriad benefits that come with reinforced concrete structures.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.