Dec . 04, 2024 09:01 Back to list

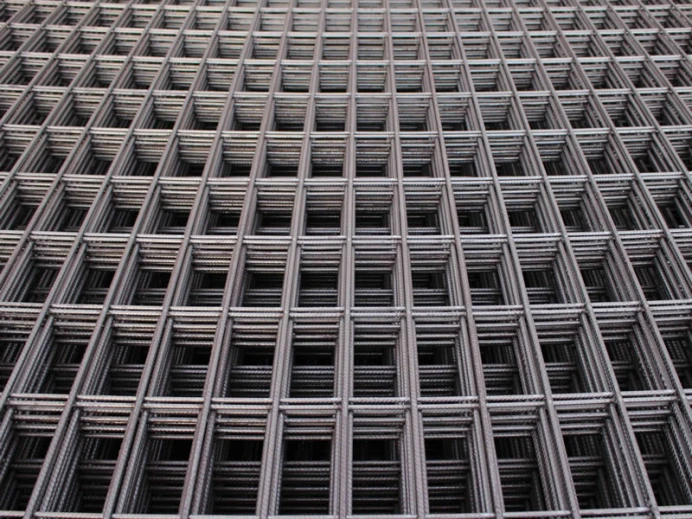

welded remesh

The Evolution of Welded Remesh in Modern Construction

In the ever-evolving world of construction, the quest for innovative materials and techniques continues to shape the industry. Among these advancements, welded remesh has emerged as a pivotal component, transforming the way structural integrity is enhanced in various applications. This article delves into the fundamental aspects of welded remesh, its advantages, and its impact on contemporary construction practices.

Welded remesh, short for welded reinforcement mesh, consists of intersecting steel wires welded at their junctions. This creates a robust grid that is primarily used to reinforce concrete structures, offering both strength and durability. Unlike traditional rebar, which requires individual placement and tying, welded remesh can be manufactured in larger sheets, providing a more efficient solution for reinforcing concrete slabs, walls, and other constructions.

One of the key benefits of welded remesh is its ability to distribute loads evenly across the entire surface area. This uniform load distribution minimizes the risk of cracking and structural failure, making it an essential component in the construction of high-stress areas such as driveways, highways, sidewalks, and even industrial flooring. By ensuring that stress is evenly dispersed, welded remesh enhances the longevity of concrete structures.

Another significant advantage of welded remesh is its cost-effectiveness. The manufacturing process allows for mass production, which reduces costs compared to traditional reinforcement methods. Additionally, since welded remesh can cover larger areas without the need for multiple pieces to be laid individually, labor costs associated with installation are also reduced. This efficiency not only benefits contractors but also contributes to overall project timelines, enabling faster completion rates.

welded remesh

Welded remesh is also known for its compatibility with various types of concrete mixes, including those that incorporate specialty additives. Whether using standard concrete or innovative high-performance mixes, welded remesh adapts well, ensuring the strength and integrity of the final structure. This flexibility makes it a favored choice among engineers and builders looking to optimize their projects for specific environmental conditions or load requirements.

The rise of sustainable construction practices has further bolstered the popularity of welded remesh. Steel, being 100% recyclable, aligns with the industry's shift towards eco-friendly materials and methods. By choosing welded remesh, builders not only enhance the performance of their projects but also contribute to reducing the overall environmental impact of construction activities. This commitment to sustainability is becoming increasingly important in a world where environmental considerations play a crucial role in material selection.

Moreover, the use of welded remesh is gaining traction in precast concrete applications. Precast elements such as panels, beams, and columns greatly benefit from the uniform reinforcement that welded remesh provides. The ability to produce these elements off-site leads to greater quality control and reduced on-site labor needs, further reinforcing the advantages of this material in modern construction projects.

Despite its numerous benefits, it is essential for construction professionals to understand the correct application of welded remesh to maximize its effectiveness. Criteria such as appropriate mesh size, wire gauge, and placement depth must be carefully considered based on specific project requirements. Furthermore, working with skilled labor to ensure proper installation techniques is vital to harness the full potential of welded remesh systems.

In conclusion, welded remesh represents a significant advancement in construction technology, offering enhanced structural integrity, efficiency, cost-effectiveness, and sustainability. As the construction landscape continues to evolve, the adoption of welded remesh is likely to grow, setting a new standard for reinforcement methods in various applications. Embracing this innovative material not only benefits builders and contractors but also paves the way for safer, more durable, and eco-friendly construction practices in the future. As we look ahead, welded remesh stands as a testament to the industry's commitment to innovation and quality, redefining the possibilities of what can be achieved in the realm of construction.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.