Feb . 17, 2025 17:36 Back to list

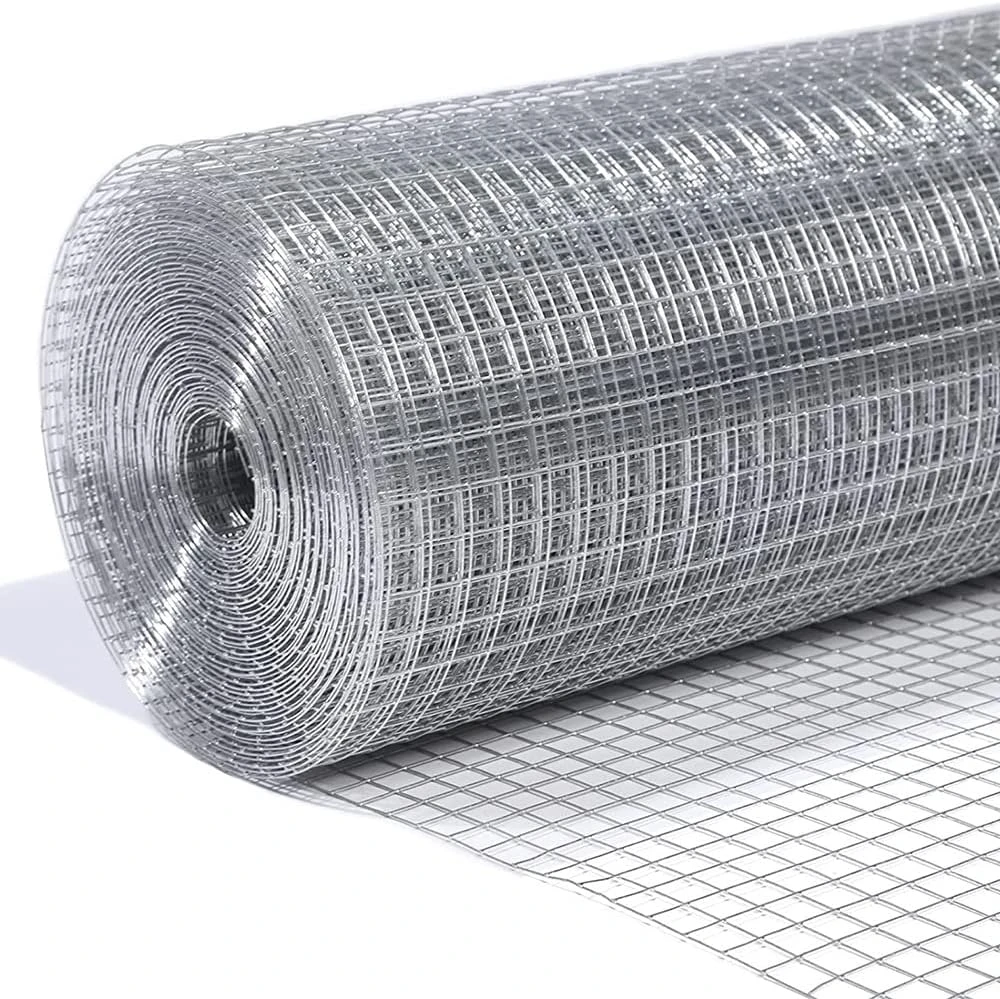

welded wire 10 gauge

Welded wire, particularly in the 10 gauge classification, serves as a cornerstone in various industrial and commercial applications. Its robust nature is a testament to its utility in construction, fencing, and infrastructure projects, among other areas.

When discussing expertise in wire products, it becomes crucial to consider the manufacturing standards and the quality control processes that these products undergo. Typically, reputable manufacturers will adhere to stringent quality assurances, ensuring that the tensile strength and durability meet the high expectations required for such applications. Welded wire 10 gauge undergoes rigorous testing to verify its capacity to endure extreme conditions, attesting to its trustworthiness in various high-stakes situations. Authoritativeness within the field of metal products can be further emphasized by discussing the protective coatings that enhance the longevity and performance of welded wire. For instance, galvanized coatings provide a significant barrier against rust and corrosion, a common concern in areas with high humidity or exposure to chemicals. Industry leaders advocate for galvanized 10 gauge wire, noting that it can maintain its structural integrity and appearance over extended periods. In fostering trustworthiness, customer testimonials and long-term industry use cases serve as compelling evidence of the 10 gauge welded wire's reliability. Clients from various sectors—from agriculture to infrastructure—vouch for its versatility and dependability. Such endorsements not only strengthen the credibility of 10 gauge welded wire but also assure potential users of its unmatched quality. Understanding and leveraging the specifics of 10 gauge welded wire can greatly enhance project outcomes across numerous fields. Its blend of strength, durability, and flexibility makes it a preferred choice for industry experts seeking not just functionality, but excellence in execution.

When discussing expertise in wire products, it becomes crucial to consider the manufacturing standards and the quality control processes that these products undergo. Typically, reputable manufacturers will adhere to stringent quality assurances, ensuring that the tensile strength and durability meet the high expectations required for such applications. Welded wire 10 gauge undergoes rigorous testing to verify its capacity to endure extreme conditions, attesting to its trustworthiness in various high-stakes situations. Authoritativeness within the field of metal products can be further emphasized by discussing the protective coatings that enhance the longevity and performance of welded wire. For instance, galvanized coatings provide a significant barrier against rust and corrosion, a common concern in areas with high humidity or exposure to chemicals. Industry leaders advocate for galvanized 10 gauge wire, noting that it can maintain its structural integrity and appearance over extended periods. In fostering trustworthiness, customer testimonials and long-term industry use cases serve as compelling evidence of the 10 gauge welded wire's reliability. Clients from various sectors—from agriculture to infrastructure—vouch for its versatility and dependability. Such endorsements not only strengthen the credibility of 10 gauge welded wire but also assure potential users of its unmatched quality. Understanding and leveraging the specifics of 10 gauge welded wire can greatly enhance project outcomes across numerous fields. Its blend of strength, durability, and flexibility makes it a preferred choice for industry experts seeking not just functionality, but excellence in execution.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.