Dec . 31, 2024 16:32 Back to list

Current Trends in Welded Wire Fabric Pricing and Market Analysis

Understanding Welded Wire Fabric Pricing Factors and Trends

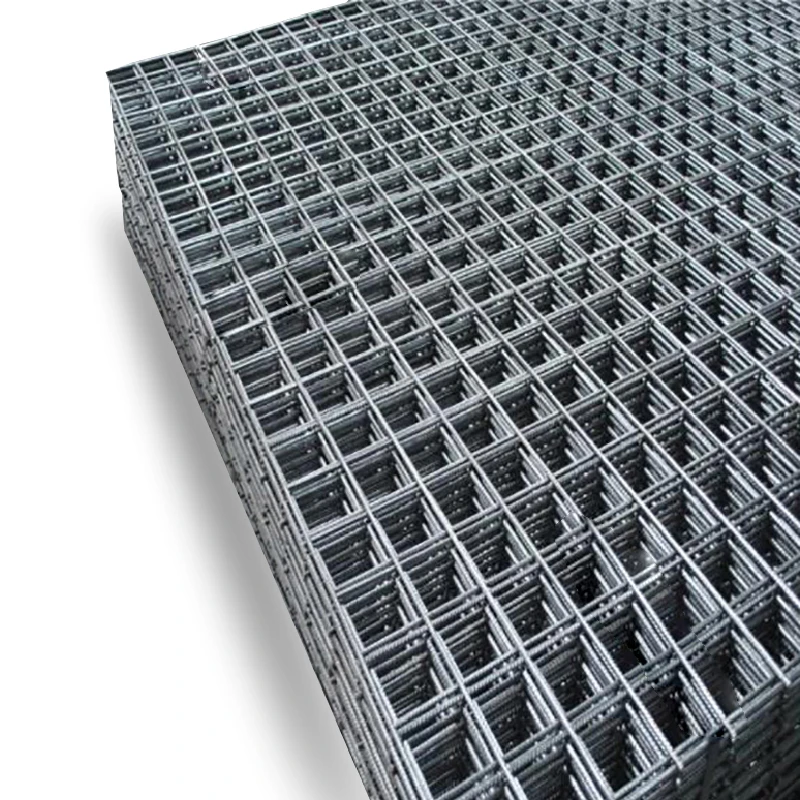

Welded wire fabric, often referred to as welded wire mesh, is a versatile construction material widely used in various applications, including reinforced concrete slabs, pavements, walls, and fencing. Its popularity stems from its strength, durability, and cost-effectiveness. However, like any commodity, the pricing of welded wire fabric can fluctuate based on a variety of factors, which can make it essential for builders, contractors, and architects to understand the pricing dynamics.

Key Factors Influencing Welded Wire Fabric Prices

1. Material Costs The primary component of welded wire fabric is steel. As such, the price of steel is the most significant factor influencing the cost of welded wire fabric. Steel prices are subject to changes based on global supply and demand, tariffs, and transportation costs. For instance, a surge in demand for steel due to booming construction activities can drive up prices.

2. Manufacturing Processes The cost of manufacturing welded wire fabric includes expenses related to labor, machinery, and overheads. Innovations in manufacturing technology can lead to lower production costs, which may subsequently reflect in the pricing of the fabric. Conversely, if production costs rise due to increased labor costs or inefficient processes, those expenses will inevitably be passed on to consumers.

3. Thickness and Mesh Size Welded wire fabric comes in various thicknesses and mesh sizes, which affect its application and, consequently, its price. Thicker wires and tighter mesh typically require more raw materials and manufacturing effort, resulting in higher costs. Understanding specific project requirements can help contractors choose the right type, balancing strength and cost.

4. Geographical Factors Location impacts the cost of welded wire fabric. Transportation costs vary depending on the distance between manufacturing facilities and construction sites. Regions that are far from manufacturing plants may incur higher delivery charges, which are factored into the final price. Additionally, local market conditions, such as competition and availability of materials, can influence pricing.

5. Market Demand The construction industry is cyclical and can fluctuate depending on economic conditions. Times of economic growth often see increased construction activity, leading to higher demand for welded wire fabric. In contrast, during economic downturns, demand may decline, which can help to stabilize or lower prices.

6. Government Regulations and Tariffs Policies affecting steel production and imports can significantly influence material costs. Tariffs on imported steel affect the overall pricing landscape for welded wire products, as domestic suppliers may adjust their prices to remain competitive. Knowing the current regulations is crucial for estimating fabric costs accurately.

welded wire fabric price

Current Trends in Pricing

As of late 2023, the welded wire fabric market has been impacted by a variety of trends. Firstly, the global economic recovery following the pandemic has led to a revitalization in construction projects, increasing demand for welded wire fabric. This demand has, in some areas, resulted in higher prices due to constrained supply.

Additionally, sustainability trends are beginning to influence pricing. Many manufacturers are increasingly focusing on producing recycled steel products. While this can sometimes lead to higher upfront costs due to the energy-intensive processes involved, it may reduce pricing volatility in the long term, appealing to eco-conscious consumers.

Making Informed Decisions

For contractors and architects, understanding the factors that influence welded wire fabric pricing is vital for budget management and project planning. To ensure the best value, it is recommended to

- Conduct Market Research Keeping abreast of current pricing trends and future forecasts can inform purchasing decisions and help in negotiating prices with suppliers. - Choose the Right Supplier Establish partnerships with reliable suppliers who offer competitive pricing and quality products. Evaluating their stability and market reputation can safeguard against future price hikes.

- Plan Ahead If possible, securing welded wire fabric early, especially during off-peak times, can help avoid inflated prices due to surges in demand.

In conclusion, while welded wire fabric remains a cost-effective solution for various construction needs, understanding the nuances of its pricing is crucial for making informed decisions. By considering factors such as material costs, manufacturing processes, and market dynamics, stakeholders can better navigate the complexities of welded wire fabric pricing.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.