Dec . 11, 2024 09:47 Back to list

Applications of Welded Wire Mesh in Reinforcing Concrete Slabs for Improved Durability

The Importance of Welded Wire Mesh for Concrete Slabs

Welded wire mesh (WWM) is an essential component in the construction industry, particularly in the reinforcement of concrete slabs. Its introduction in concrete structures significantly enhances their strength, durability, and overall structural integrity. This article delves into the various advantages and applications of welded wire mesh, highlighting its role in modern construction.

Understanding Welded Wire Mesh

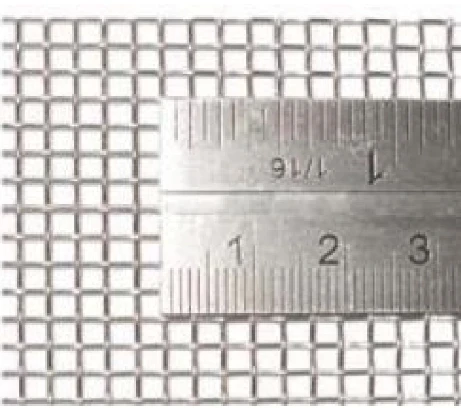

Welded wire mesh is made by intertwining steel wires in a grid pattern and welding them at the intersections. This method creates a strong and rigid framework that can be easily positioned within concrete forms. The mesh typically comes in various sizes, gauges, and patterns, allowing for customization based on specific project requirements.

Benefits of Using Welded Wire Mesh in Concrete Slabs

1. Enhanced Structural Integrity One of the primary functions of welded wire mesh is to provide tensile strength to concrete slabs. Concrete is strong in compression but weak in tension. The incorporation of welded wire mesh helps to address this weakness by distributing loads across the slab, thereby helping to prevent cracks.

2. Crack Control Concrete is susceptible to cracking due to temperature fluctuations, hydration shrinkage, and settling. By using welded wire mesh, contractors can effectively control and minimize these cracks. The mesh acts as a barrier, restraining the spread of cracks and ensuring that they do not compromise the slab's structural integrity.

3. Ease of Installation Welded wire mesh is lightweight and easy to handle, which simplifies the installation process. It can be rolled out and cut to fit the dimensions of the project. This ease of handling makes it a favored choice among contractors, saving both time and labor costs during installation.

4. Versatility Welded wire mesh is applicable in a variety of construction scenarios. From residential driveways and patios to industrial floors and commercial buildings, its versatility makes it suitable for any concrete slab application.

welded wire mesh for concrete slabs

5. Cost-Effectiveness Although the initial cost of welded wire mesh can be higher than other reinforcement methods, its long-term benefits often outweigh the upfront investment. The durability it provides can lead to lower maintenance costs over time, making it a cost-effective solution for many projects.

Applications of Welded Wire Mesh

Welded wire mesh is commonly used in various applications, including

- Residential Construction In homes, welded wire mesh is frequently used in garage floors, driveways, and basements to provide additional support and prevent cracking. - Commercial and Industrial Projects For warehouses, factories, and loading docks, the strength provided by welded wire mesh is crucial for supporting heavy loads and continuous traffic.

- Pavements and Sidewalks Many municipalities recognize the advantages of using welded wire mesh in sidewalks and roadways, as it enhances their lifespan and resistance to cracking.

- Precast Concrete Welded wire mesh is also utilized in precast concrete elements, such as slabs and panels, allowing for efficient construction and transport.

Conclusion

Welded wire mesh plays a pivotal role in modern construction, particularly in reinforcing concrete slabs. Its ability to enhance structural integrity, control cracking, and provide a cost-effective solution makes it an indispensable material in the construction industry. Whether in residential or commercial projects, the benefits of welded wire mesh cannot be overlooked, as it contributes significantly to the longevity and safety of concrete structures. As construction methods continue to evolve, the adoption of welded wire mesh will likely increase, keeping pace with the demands for stronger and more durable infrastructure.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.