Jan . 01, 2025 11:04 Back to list

Welded Wire Mesh Dimensions and Weight Specifications for Various Uses

Understanding Welded Wire Mesh Sizes and Weights

Welded wire mesh is a versatile and widely used construction material, essential in various applications, from agriculture to civil engineering. Understanding the different sizes and weights of welded wire mesh can help you choose the right product for your specific needs. In this article, we will examine the key factors regarding the sizes and weights of welded wire mesh, enabling you to make informed decisions for your projects.

What is Welded Wire Mesh?

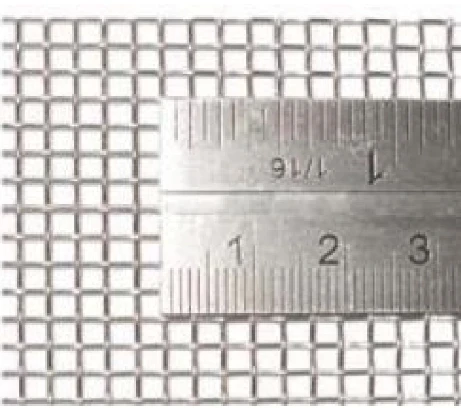

Welded wire mesh consists of a grid of steel wires that are welded together at their intersections. The wires can vary in diameter and spacing, depending on the application requirements. Welded wire mesh is noted for its high strength, durability, and resistance to deformation, making it ideal for a plethora of applications, such as fencing, concrete reinforcement, and agricultural uses.

Sizes of Welded Wire Mesh

Welded wire mesh comes in various sizes, and the selection largely depends on the intended use. The mesh is typically categorized by the diameter of the wire and the spacing between the wires

1. Wire Diameter Common wire diameters range from 14 gauge (approximately 2.0 mm) to 6 gauge (approximately 4.0 mm). Thicker wires provide increased strength and stability, which is often required in construction applications, while thinner wires might suffice for light domestic or agricultural work.

2. Opening Size The opening size of the mesh can vary significantly, typically ranging from 1 inch to 6 inches. Smaller openings are suitable for applications requiring containment of smaller objects, while larger openings are ideal for situations where drainage or airflow is crucial.

welded wire mesh sizes and weights

3. Sheet Dimensions Welded wire mesh is available in different sheet sizes, with common dimensions such as 4 feet by 8 feet. Custom sizes can often be ordered, allowing for flexibility depending on specific project needs.

Weights of Welded Wire Mesh

The weight of welded wire mesh is an essential consideration, particularly for transportation and installation purposes. The weight can vary based on the wire gauge, the size of openings, and the overall dimensions of the sheet. Generally, heavier meshes can offer greater tensile strength and are suitable for more demanding applications.

1. Calculating Weight The weight of welded wire mesh can be calculated using a simple formula Weight (lbs) = (Length in ft x Width in ft x Wire Diameter in inches^2 x 490) / 1000. This calculation provides an estimate of the total weight based on the dimensions and wire specifications.

2. Common Weights For example, a standard 4x8 foot sheet made from 6-gauge wire might weigh around 90 to 100 pounds, while a 4x10 foot sheet with a 14-gauge wire could weigh closer to 50 pounds. Knowing these weights helps in planning the logistics of transportation and installation.

Conclusion

In summary, the sizes and weights of welded wire mesh are critical factors to consider when selecting the right product for your project. By understanding the different mesh designs, wire gauges, opening sizes, and their respective weights, you can ensure optimal performance and safety in your application.

Whether you are constructing a fence, reinforcing a concrete slab, or needing a sturdy solution for agricultural uses, the right welded wire mesh can provide the strength and durability you require. To make the best choice, always consult with suppliers and consider your specific project requirements before making a purchase. With the right information on welded wire mesh sizes and weights, you can ensure a successful and efficient project every time.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.