Nov . 19, 2024 20:52 Back to list

welded wire reinforcement

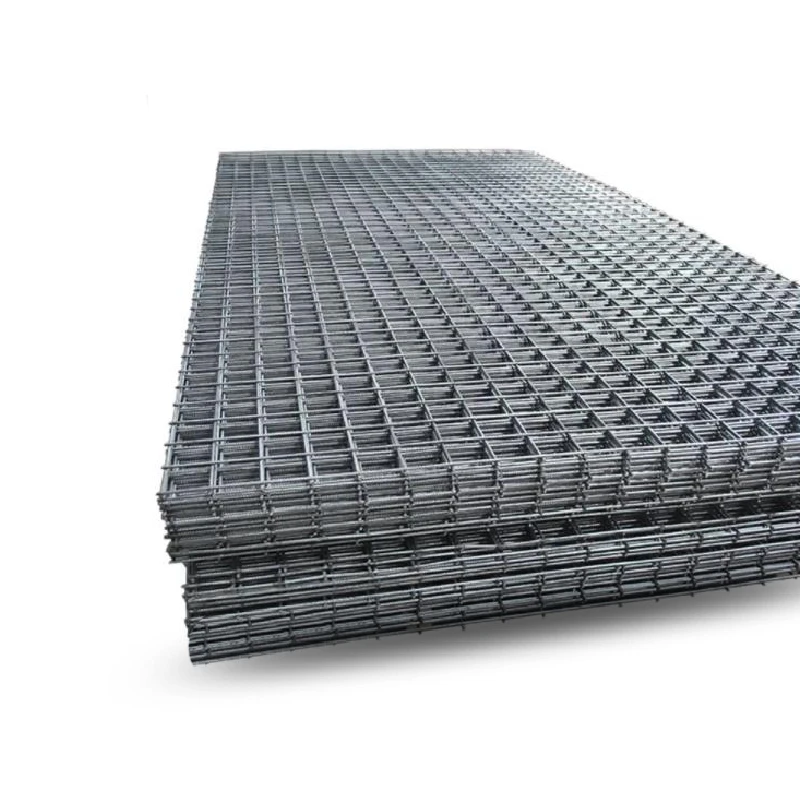

Welded Wire Reinforcement A Key Component in Modern Construction

In the ever-evolving field of construction, the need for robust and durable building materials is paramount. One such material that has gained prominence over the years is welded wire reinforcement (WWR). This innovative reinforcer combines the benefits of traditional steel reinforcement with modern manufacturing techniques, offering a multitude of advantages for various construction applications.

What is Welded Wire Reinforcement?

Welded wire reinforcement consists of a series of steel wires laid out in a grid pattern and welded at the intersections. The result is a strong, uniform mesh that can be used to enhance the structural integrity of concrete elements. WWR is primarily used in slabs, walls, and pavements, providing essential tensile strength to counteract cracking and bending stresses that occur in concrete structures.

Advantages of Welded Wire Reinforcement

1. Enhanced Structural Integrity One of the most significant advantages of using WWR is its ability to improve the overall strength and durability of concrete structures. Concrete is inherently strong under compression but weak under tension. The incorporation of welded wire reinforcement distributes tensile loads more evenly, reducing the likelihood of cracks and structural failures.

2. Cost-Effectiveness WWR can often be more economical than traditional reinforcement methods. The production process allows for precise control over material usage, minimizing waste. Moreover, the quick installation of welded wire fabrics can lead to reduced labor costs, making WWR an attractive option for builders and contractors looking to stay within tight budgets.

3. Speed of Installation WWR comes in rolls or sheets, which are easy to transport and handle on-site. The installation process is significantly faster than placing individual rebar, allowing for quicker project turnaround times. This efficiency is especially valuable in large-scale construction projects where time is of the essence.

4. Improved Crack Control The uniform grid of welded wire reinforcement helps control cracking in concrete by providing additional tensile strength at closely spaced intervals. This capability is particularly beneficial in areas prone to shrinkage and temperature variations, as it helps to mitigate the effects of environmental stresses on the concrete.

welded wire reinforcement

5. Versatility Welded wire reinforcement can be adapted to a variety of construction projects, from residential homes to industrial facilities. Its flexibility in design makes it suitable for both horizontal and vertical applications, allowing engineers and architects to utilize it in innovative ways.

Applications of Welded Wire Reinforcement

WWR is commonly used in a spectrum of construction applications, including

- Slabs on Grade In residential and commercial buildings, WWR is often used in slabs to provide the necessary strength and support. It helps to prevent cracking and ensures longevity under heavy loads.

- Pavements Roads and highways benefit from WWR, which enhances pavement durability and performance. By integrating welded wire fabrics, constructors can create more resilient surfaces that can withstand traffic wear and environmental factors.

- Walls and Foundations Vertical elements such as retaining walls and foundations also utilize WWR to provide additional reinforcement against lateral loads and soil pressure, ensuring structural stability.

- Precast Concrete In the realm of precast concrete elements, WWR can be easily integrated into products such as panels and beams, streamlining the manufacturing process while enhancing product quality.

Conclusion

Welded wire reinforcement is a vital component in modern construction, offering a perfect blend of strength, efficiency, and cost-effectiveness. Its ability to improve the structural integrity of concrete while minimizing labor costs and installation time makes it a preferred choice for engineers and construction professionals worldwide. As the construction industry continues to evolve, WWR is likely to play an increasingly significant role in building durable and sustainable structures that meet the demands of contemporary society. By investing in advanced materials like welded wire reinforcement, we are not only enhancing the quality of our constructions but also contributing to more resilient infrastructure for future generations.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.