Dec . 25, 2024 12:41 Back to list

Understanding Different Sizes of Welded Wire Reinforcement for Construction Applications

Understanding Welded Wire Reinforcement Sizes

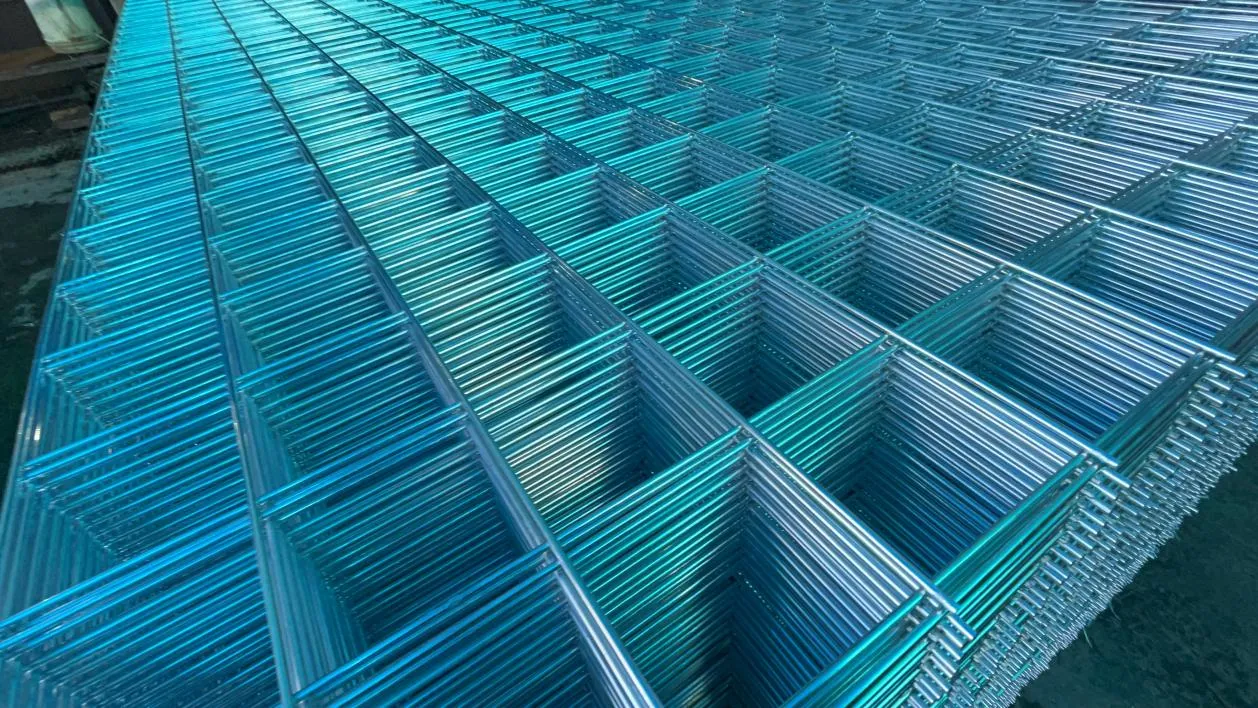

Welded wire reinforcement (WWR) plays a pivotal role in modern construction, providing crucial structural support in various applications. It consists of cross wires that are welded together at intersections, forming a mesh-like structure. This method of reinforcement is favored for its reliability, economy, and efficiency in enhancing the tensile strength of concrete and masonry. Understanding the sizes and specifications of welded wire reinforcement is essential for engineers, architects, and construction professionals involved in any building or infrastructure project.

The Importance of WWR Sizes

The size of welded wire reinforcement is paramount in determining the load-bearing capacity and overall performance of a structure. WWR comes in various sizes and grid patterns, which can be tailored to meet specific engineering requirements. The dimensions typically refer to the spacing between wires (in inches or millimeters) and the diameter of the wires themselves.

Welded wire reinforcement sizes are standardized according to specifications set by organizations such as the American Concrete Institute (ACI) and the Wire Reinforcement Institute (WRI). These standards ensure that WWR is manufactured consistently and meets the required strength and durability standards for construction applications.

Common Sizes and Specifications

WWR is classified based on its wire diameter and spacing. The wire diameter can range from 8 to 18 gauge, where the lower the gauge number, the thicker the wire. The spacing between the wires is usually described in terms of the distance between longitudinal and transverse wires, such as 4x4 inches or 6x6 inches.

A common type is W4.0 x W4.0, which indicates that the mesh consists of wires that are 4 gauge in diameter with a spacing of 4 inches in both directions. This kind of configuration is typically used in residential slabs and driveways. Larger mesh sizes, such as W6.0 x W6.0 or W8.0 x W8.0, can be employed for applications needing additional support, like industrial floors or bridges.

Selection Criteria

Choosing the appropriate size of welded wire reinforcement hinges on multiple factors, including

welded wire reinforcement sizes

1. Load Requirements The expected loads on the structure dictate the size and spacing of the reinforcement. Heavier loads will necessitate thicker wires and closer spacing.

2. Concrete Thickness The thickness of the concrete slab or wall significantly influences the selection of WWR size. Thicker materials may distribute loads more effectively, allowing for different reinforcement configurations.

3. Project Specifications Local building codes, design plans, and project specifications provide guidelines about the necessary strength and durability, helping determine the sizes that should be used.

4. Environmental Conditions Exposure conditions and the environment may impact the choice of reinforcement sizes as well. For instance, in areas prone to seismic activity, additional reinforcement may be required.

Installation Best Practices

Proper installation of welded wire reinforcement is critical to ensuring its effectiveness. The mesh should be placed in the center of the concrete slab to effectively carry tensile forces. It is also essential to avoid any overlap or gaps between the sheets of WWR, which could lead to weaknesses in the structure.

Concrete should be carefully poured and consolidated around the reinforcement to eliminate air pockets, which could compromise the bond between the concrete and the wires. Additionally, ensuring adequate coverage of concrete over the mesh is vital to protect it from corrosion and environmental damage.

Conclusion

Welded wire reinforcement sizes are a fundamental aspect of structural design, impacting the integrity and stability of buildings and infrastructure. By understanding the specifications and selecting the appropriate sizes based on project requirements, professionals in construction can enhance the performance and longevity of their projects. Whether for residential, commercial, or industrial applications, WWR remains a reliable choice for reinforced concrete structures. Proper knowledge and application of these sizes contribute to the overall success and safety of construction endeavors.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.