Feb . 08, 2025 01:09 Back to list

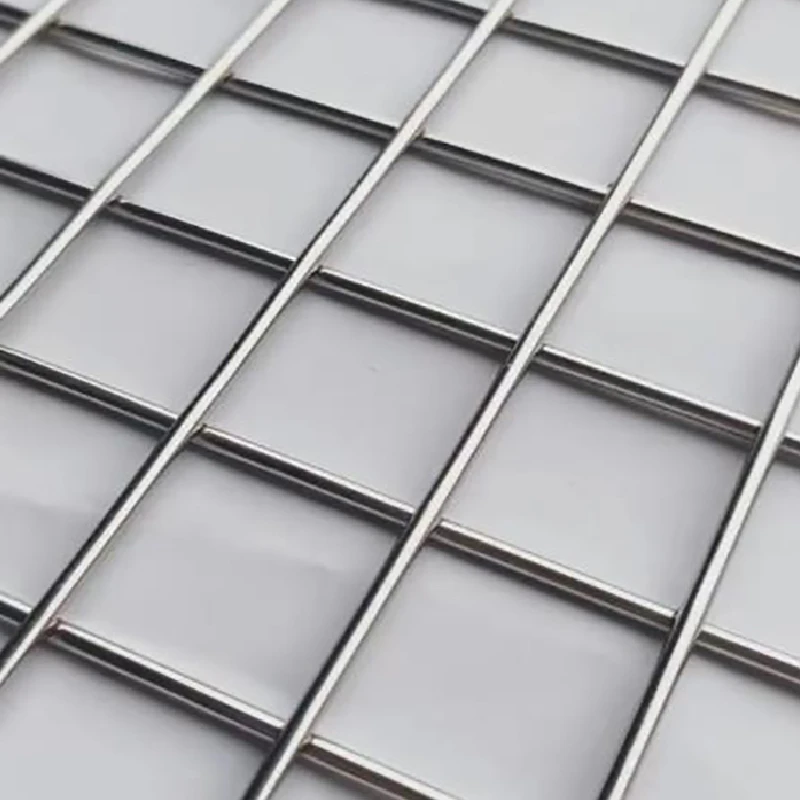

weld mesh for concrete

Welded mesh for concrete reinforcement has emerged as a critical element in modern construction, offering a blend of efficiency and strength. For those in the construction industry, understanding its core advantages and applications can lead to substantial improvements in project outcomes. Here's an in-depth exploration based on firsthand experiences and expert insights.

Authority in the field of construction materials comes from extensive research and successful implementation across various projects. Studies by recognized institutions support the use of welded mesh, evidencing its superior performance in stress distribution and crack control. These findings have led to its widespread acceptance in infrastructural projects, such as bridges, tunnels, and large-scale commercial developments. Trustworthiness in recommending welded mesh lies in its proven track record and compliance with international quality standards. Many leading construction firms report significant enhancements in project delivery times and structural reliability after switching to welded mesh systems. Furthermore, ongoing quality checks and certifications ensure that only the best materials reach the market, providing peace of mind to construction managers and stakeholders alike. An important consideration for those opting to use welded mesh is the sourcing of reliable manufacturers. Professionals in the industry often emphasize the importance of selecting suppliers who maintain strict adherence to quality management systems. This step is vital to ensuring the mesh meets all necessary specifications and guidelines, thereby safeguarding the project's success. In conclusion, integrating welded mesh into concrete structures presents a multitude of benefits that cannot be overlooked. Its combination of strength, ease of use, and durability makes it an indispensable component in modern construction. By choosing welded mesh, stakeholders and builders can deliver projects that not only meet current demands but also stand the test of time, gaining a competitive edge in a challenging industry landscape.

Authority in the field of construction materials comes from extensive research and successful implementation across various projects. Studies by recognized institutions support the use of welded mesh, evidencing its superior performance in stress distribution and crack control. These findings have led to its widespread acceptance in infrastructural projects, such as bridges, tunnels, and large-scale commercial developments. Trustworthiness in recommending welded mesh lies in its proven track record and compliance with international quality standards. Many leading construction firms report significant enhancements in project delivery times and structural reliability after switching to welded mesh systems. Furthermore, ongoing quality checks and certifications ensure that only the best materials reach the market, providing peace of mind to construction managers and stakeholders alike. An important consideration for those opting to use welded mesh is the sourcing of reliable manufacturers. Professionals in the industry often emphasize the importance of selecting suppliers who maintain strict adherence to quality management systems. This step is vital to ensuring the mesh meets all necessary specifications and guidelines, thereby safeguarding the project's success. In conclusion, integrating welded mesh into concrete structures presents a multitude of benefits that cannot be overlooked. Its combination of strength, ease of use, and durability makes it an indispensable component in modern construction. By choosing welded mesh, stakeholders and builders can deliver projects that not only meet current demands but also stand the test of time, gaining a competitive edge in a challenging industry landscape.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.