Feb . 18, 2025 05:24 Back to list

what is weld mesh

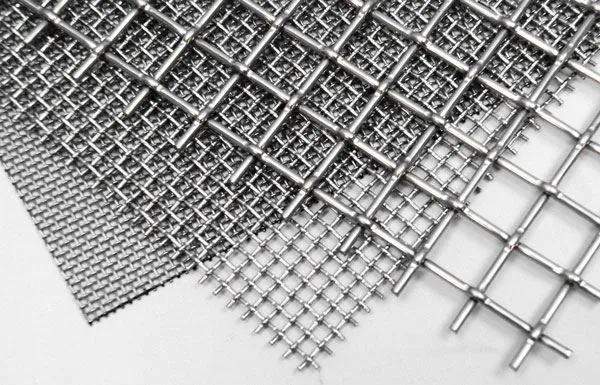

Welded mesh, often referred to as weld mesh, is a versatile product fabricated by welding individual low carbon steel wires at each intersection. Its robustness, cost-effectiveness, and adaptability make it an essential component across various industries, affirming its prevalent usage globally.

Furthermore, the customization potential of weld mesh cannot be overlooked. It is possible to coat welded mesh with protective materials, such as galvanization or PVC, to enhance its resistance to corrosion. This adaptability extends its usability in offshore structures, marine environments, and external architectural features where resistance to oxidization and weathering is paramount. When considering cost, welded mesh offers an economic advantage. The efficiency of its manufacturing process reduces production costs, making it an affordable option without compromising quality and reliability. Its installation is straightforward, which minimizes labor expenses and time, adding to its overall cost-effectiveness for large and small-scale projects alike. Security and safety are paramount, and weld mesh delivers on these fronts exceptionally well. It's used extensively in designing secure facilities, such as prisons or high-security buildings, where its rigid structure can prevent tampering and unauthorized access effectively. The mesh can be configured into different height and barb designs, enhancing its deterrent effects. The trustworthiness and efficacy of weld mesh are supported by extensive experience and expertise accumulated over decades of use. Professionals in engineering, architecture, and agriculture consistently recommend welded mesh due to its proven performance and reliability. It stands as a testament to engineering excellence where simplicity meets functionality, ensuring it remains an invaluable resource for diverse applications. In summary, weld mesh is not just a product; it is a foundational element that supports and enhances modern infrastructure and industries. Its enduring popularity across various fields is a testament to its unparalleled combination of strength, flexibility, and cost-effectiveness. Recognizing the unique advantages of weld mesh paves the way for innovative uses and broader applications, solidifying its status as an indispensable material in today's world.

Furthermore, the customization potential of weld mesh cannot be overlooked. It is possible to coat welded mesh with protective materials, such as galvanization or PVC, to enhance its resistance to corrosion. This adaptability extends its usability in offshore structures, marine environments, and external architectural features where resistance to oxidization and weathering is paramount. When considering cost, welded mesh offers an economic advantage. The efficiency of its manufacturing process reduces production costs, making it an affordable option without compromising quality and reliability. Its installation is straightforward, which minimizes labor expenses and time, adding to its overall cost-effectiveness for large and small-scale projects alike. Security and safety are paramount, and weld mesh delivers on these fronts exceptionally well. It's used extensively in designing secure facilities, such as prisons or high-security buildings, where its rigid structure can prevent tampering and unauthorized access effectively. The mesh can be configured into different height and barb designs, enhancing its deterrent effects. The trustworthiness and efficacy of weld mesh are supported by extensive experience and expertise accumulated over decades of use. Professionals in engineering, architecture, and agriculture consistently recommend welded mesh due to its proven performance and reliability. It stands as a testament to engineering excellence where simplicity meets functionality, ensuring it remains an invaluable resource for diverse applications. In summary, weld mesh is not just a product; it is a foundational element that supports and enhances modern infrastructure and industries. Its enduring popularity across various fields is a testament to its unparalleled combination of strength, flexibility, and cost-effectiveness. Recognizing the unique advantages of weld mesh paves the way for innovative uses and broader applications, solidifying its status as an indispensable material in today's world.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.