Jan . 09, 2025 10:46 Back to list

stacked slate cladding

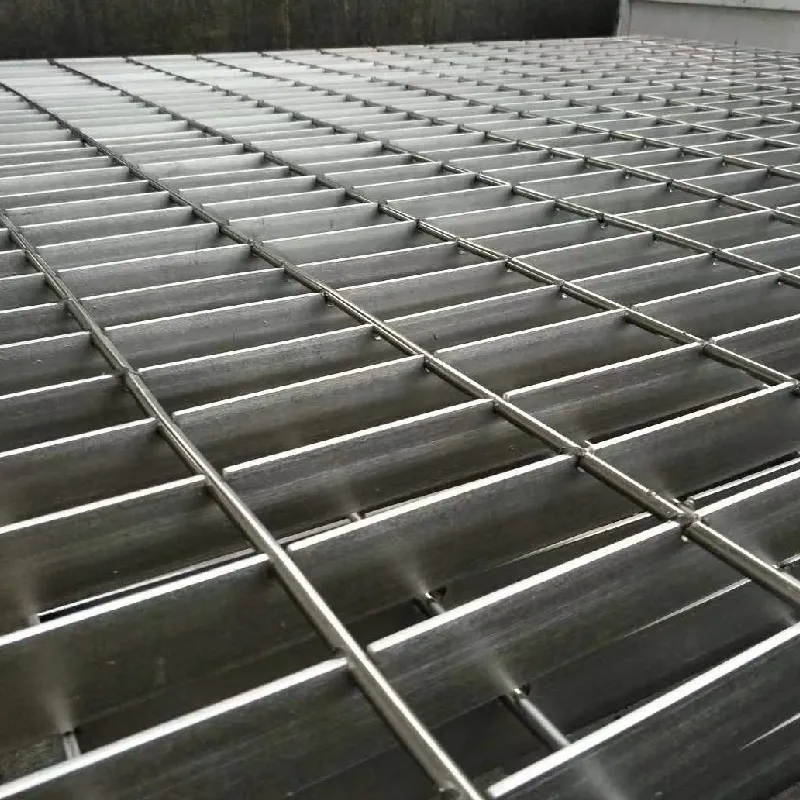

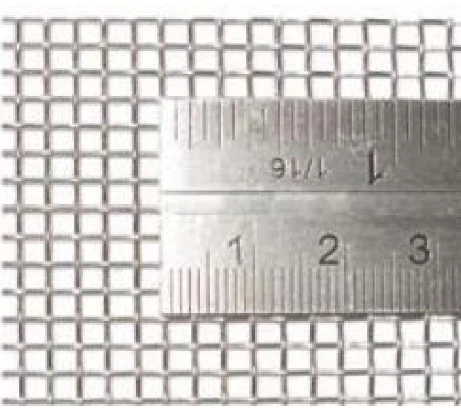

Wire mesh fabricators are the unsung heroes of numerous industries, providing essential products that merge functionality with innovation. With expertise rooted in precision engineering, these fabricators create versatile solutions that are integral to countless applications, from construction to creative design landscapes.

Trustworthiness in this domain is built on the foundation of consistent quality and timely delivery. Repeat collaborations with industries like aerospace, automotive, and agribusiness affirm a fabricator's reliability. The ability to customize solutions to meet unique specifications—whether through advanced 3D modeling or prototype development—amplifies trust amongst clients. This bespoke approach results in optimized end-user experiences and minimized project downtime. The future of wire mesh fabrication is marked by technological progressions, such as the incorporation of automation and smart manufacturing systems. These advancements promise enhanced precision, reduced waste, and the ability to tackle complex, large-scale projects efficiently. A proactive approach toward adopting such innovations positions fabricators as leaders who do more than just keep pace—they set the benchmark for industry standards. Furthermore, sustainability has become a crucial focus. Eco-friendly practices, like using recycled materials and minimizing carbon footprints during production, reflect a fabricator's commitment to environmental responsibility—a quality increasingly demanded by conscious consumers globally. My journey through the world of wire mesh fabricators has cemented my appreciation for their role in shaping modern infrastructure and products. These fabricators offer more than material; they provide tailored, reliable solutions that embody expertise and authority. As industries evolve, wire mesh fabricators stand ready to meet new challenges with innovative, trustworthy practices that continue to pave the way for advancements in design and functionality.

Trustworthiness in this domain is built on the foundation of consistent quality and timely delivery. Repeat collaborations with industries like aerospace, automotive, and agribusiness affirm a fabricator's reliability. The ability to customize solutions to meet unique specifications—whether through advanced 3D modeling or prototype development—amplifies trust amongst clients. This bespoke approach results in optimized end-user experiences and minimized project downtime. The future of wire mesh fabrication is marked by technological progressions, such as the incorporation of automation and smart manufacturing systems. These advancements promise enhanced precision, reduced waste, and the ability to tackle complex, large-scale projects efficiently. A proactive approach toward adopting such innovations positions fabricators as leaders who do more than just keep pace—they set the benchmark for industry standards. Furthermore, sustainability has become a crucial focus. Eco-friendly practices, like using recycled materials and minimizing carbon footprints during production, reflect a fabricator's commitment to environmental responsibility—a quality increasingly demanded by conscious consumers globally. My journey through the world of wire mesh fabricators has cemented my appreciation for their role in shaping modern infrastructure and products. These fabricators offer more than material; they provide tailored, reliable solutions that embody expertise and authority. As industries evolve, wire mesh fabricators stand ready to meet new challenges with innovative, trustworthy practices that continue to pave the way for advancements in design and functionality.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.