Jan . 09, 2025 10:58 Back to list

Expert Wire Mesh Fabricators for Durable Solutions

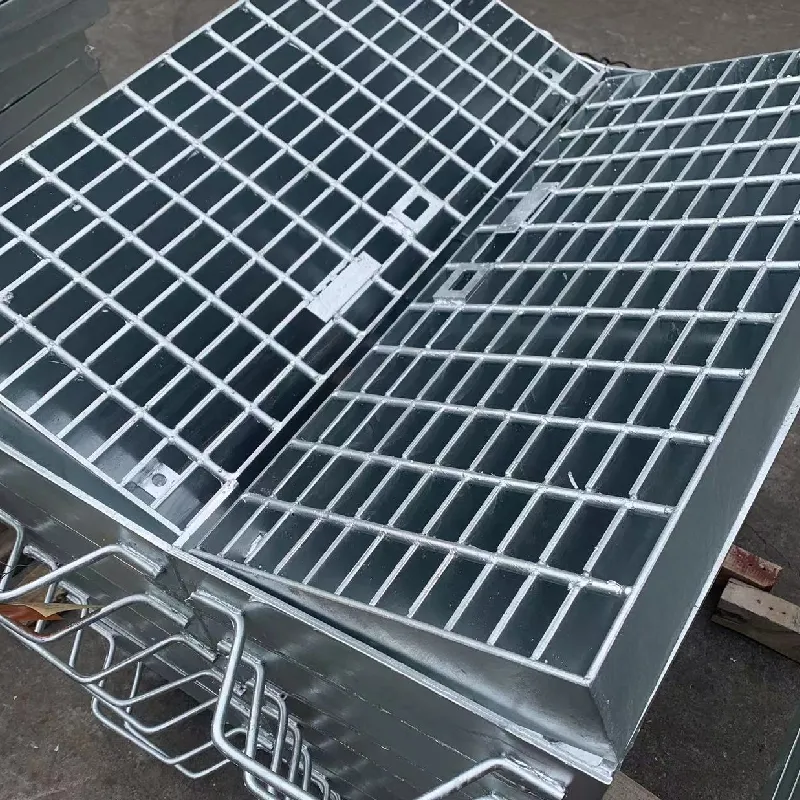

Wire mesh fabricators play a crucial role in various industries, supplying products that are not only versatile but also fundamental in applications ranging from construction to industrial processes. The expertise that these fabricators bring to the table is unparalleled, and it is important to delve into the specifics of their craft to appreciate their significance fully.

In the real world, the experience of a wire mesh fabricator is evidenced by their portfolio of past projects, demonstrating a track record of successful implementations across various sectors. For instance, in construction, wire mesh is essential for providing reinforcement in concrete structures, preventing cracking, and ensuring the longevity of the building. In the agricultural industry, it plays a pivotal role in fencing, enclosures, and pest control systems, all areas where durability and resistance to environmental elements are crucial. Additionally, industries such as automotive and aerospace rely on the precision and resilience of wire mesh in the manufacture of filters, grilles, and protective covers. The product knowledge that professional wire mesh fabricators possess extends beyond the basic features and applications of their products. They are adept at advising clients on the best material and weave type for their specific applications, factoring in variables like load demands, environmental exposure, and budget constraints. This ability to offer customized advice underscores their expertise and positions them as an invaluable resource in project planning and execution. Ultimately, the true success of wire mesh fabrication is measured by its performance in real-world applications. Experienced fabricators continuously gather data and feedback from the field to refine their products and processes. This cycle of improvement is driven by a commitment to excellence and a desire to meet the ever-evolving needs of industries that depend on wire mesh technology. Wire mesh fabricators are not merely suppliers of a product; they are partners in innovation and efficiency. Through a blend of technical prowess, rigorous standards, and unwavering dedication to quality, they ensure that their mesh solutions not only meet but exceed the expectations of their clients. It is this blend of experience, expertise, authority, and trust that solidifies their reputation as industry leaders.

In the real world, the experience of a wire mesh fabricator is evidenced by their portfolio of past projects, demonstrating a track record of successful implementations across various sectors. For instance, in construction, wire mesh is essential for providing reinforcement in concrete structures, preventing cracking, and ensuring the longevity of the building. In the agricultural industry, it plays a pivotal role in fencing, enclosures, and pest control systems, all areas where durability and resistance to environmental elements are crucial. Additionally, industries such as automotive and aerospace rely on the precision and resilience of wire mesh in the manufacture of filters, grilles, and protective covers. The product knowledge that professional wire mesh fabricators possess extends beyond the basic features and applications of their products. They are adept at advising clients on the best material and weave type for their specific applications, factoring in variables like load demands, environmental exposure, and budget constraints. This ability to offer customized advice underscores their expertise and positions them as an invaluable resource in project planning and execution. Ultimately, the true success of wire mesh fabrication is measured by its performance in real-world applications. Experienced fabricators continuously gather data and feedback from the field to refine their products and processes. This cycle of improvement is driven by a commitment to excellence and a desire to meet the ever-evolving needs of industries that depend on wire mesh technology. Wire mesh fabricators are not merely suppliers of a product; they are partners in innovation and efficiency. Through a blend of technical prowess, rigorous standards, and unwavering dedication to quality, they ensure that their mesh solutions not only meet but exceed the expectations of their clients. It is this blend of experience, expertise, authority, and trust that solidifies their reputation as industry leaders.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.