Jan . 09, 2025 13:44 Back to list

popular exterior decoration natural stacked stone panel

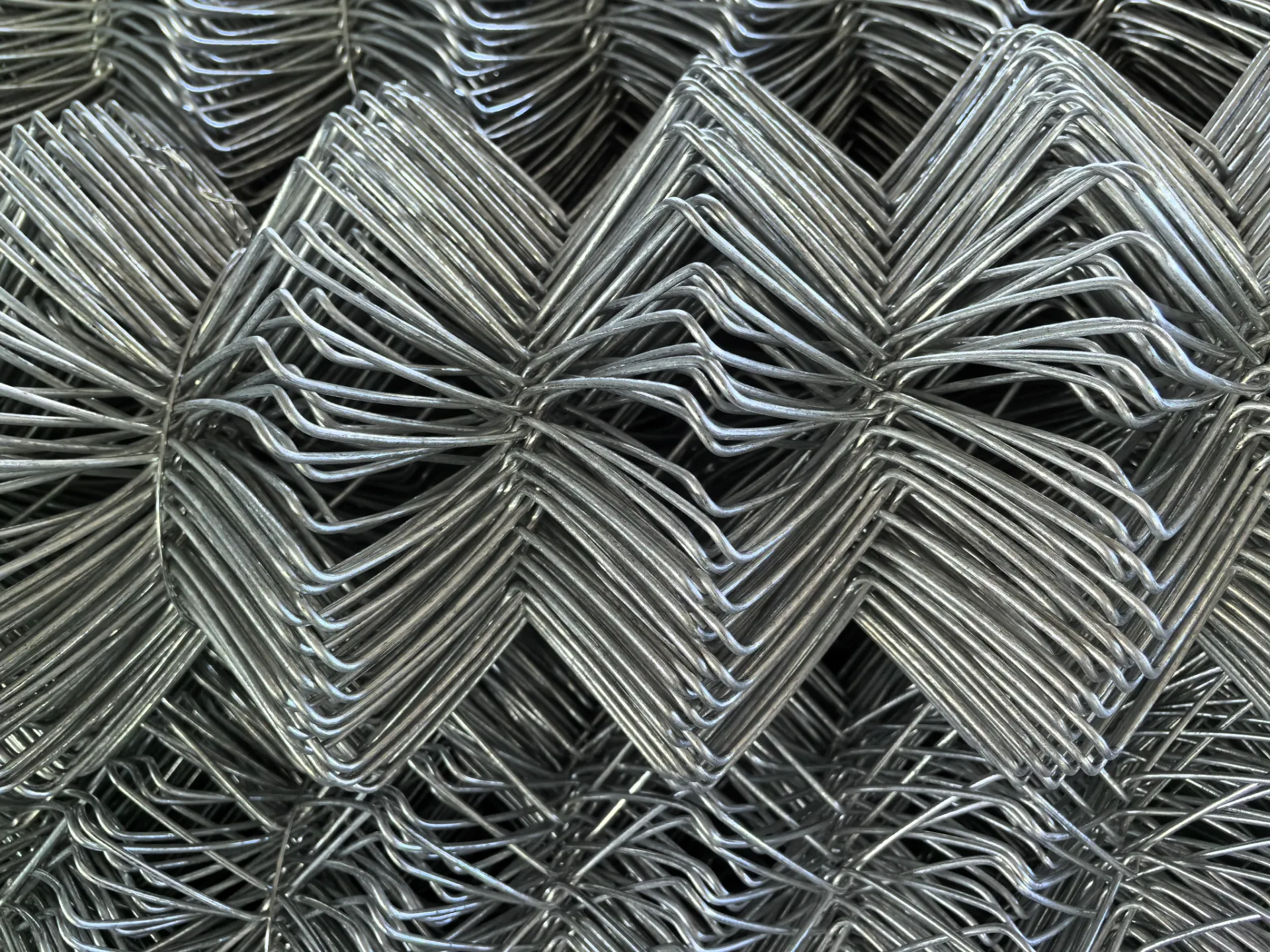

Navigating the Realm of Wire Mesh Fabricators Insights from the Field

Authoritativeness in this domain is cultivated through the construction of a robust network of professional relationships. Collaborating with civil engineers, architects, and project managers not only broadens one's perspective but also cements one's position as a trusted advisor in the industry. This network becomes especially critical in understanding industry standards, such as ASTM and ISO, ensuring that all fabrications align with global benchmarks for safety and performance. In particular, my contribution to a panel that revised the safety protocols for high-impact meshes has been a pivotal point of my authoritative standing within the community. Trustworthiness, the bedrock of any enduring business relationship, is meticulously earned in the realm of wire mesh fabrication. Customers and clients frequently depend on the fabricator's judgment to deliver on time, within scope, and up to the rigorous quality expected. Implementing a transparent process that involves regular updates, clear communication of potential challenges, and firsthand site inspections reinforces confidence and reliability. A noteworthy project involved nationwide farmers, where despite logistical hurdles, creating durable, effective fencing solutions for large-scale operations cemented my reputation for accountability and dedication. Thus, the landscape of wire mesh fabricating is rich with opportunities for those who combine experience, expertise, authoritativeness, and trustworthiness. Each project tells a story not just of material and method, but of human ingenuity and resilience. As industries evolve, so too must the fabricator, adapting and innovating to meet the ever-changing tides of demand and technology—an endeavor that remains as challenging as it is rewarding.

Authoritativeness in this domain is cultivated through the construction of a robust network of professional relationships. Collaborating with civil engineers, architects, and project managers not only broadens one's perspective but also cements one's position as a trusted advisor in the industry. This network becomes especially critical in understanding industry standards, such as ASTM and ISO, ensuring that all fabrications align with global benchmarks for safety and performance. In particular, my contribution to a panel that revised the safety protocols for high-impact meshes has been a pivotal point of my authoritative standing within the community. Trustworthiness, the bedrock of any enduring business relationship, is meticulously earned in the realm of wire mesh fabrication. Customers and clients frequently depend on the fabricator's judgment to deliver on time, within scope, and up to the rigorous quality expected. Implementing a transparent process that involves regular updates, clear communication of potential challenges, and firsthand site inspections reinforces confidence and reliability. A noteworthy project involved nationwide farmers, where despite logistical hurdles, creating durable, effective fencing solutions for large-scale operations cemented my reputation for accountability and dedication. Thus, the landscape of wire mesh fabricating is rich with opportunities for those who combine experience, expertise, authoritativeness, and trustworthiness. Each project tells a story not just of material and method, but of human ingenuity and resilience. As industries evolve, so too must the fabricator, adapting and innovating to meet the ever-changing tides of demand and technology—an endeavor that remains as challenging as it is rewarding.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

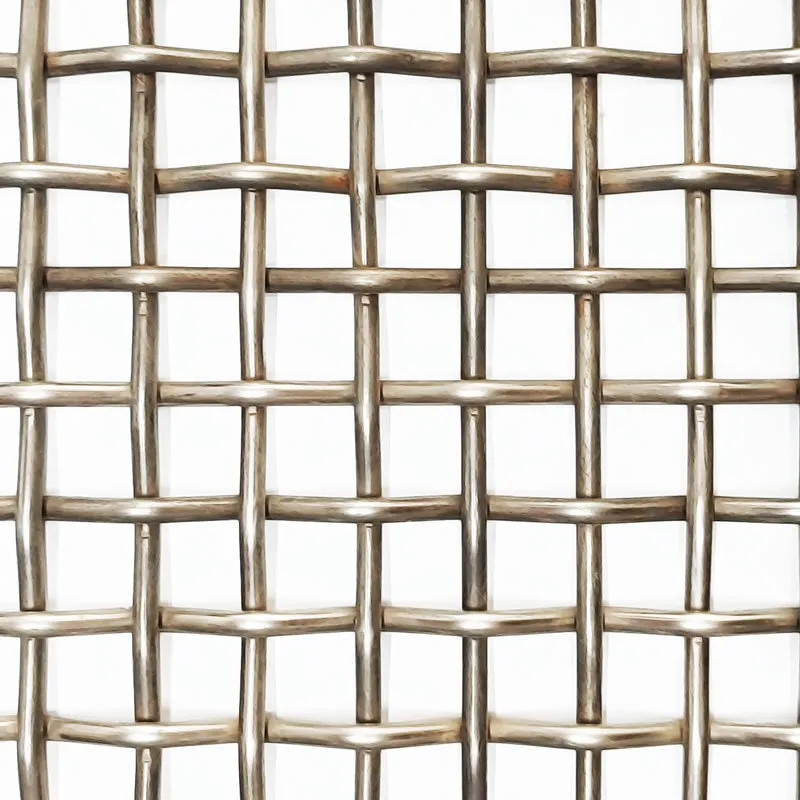

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.