Jan . 06, 2025 18:54 Back to list

popular exterior decoration natural stacked stone panel

Navigating through the intricacies of a wire mesh factory unveils a fascinating interplay of engineering, precision, and innovation. Within the industrial landscape, wire mesh plays an indomitable role, woven intricately to serve sectors ranging from construction to technology. This article explores the unique essence of a wire mesh factory, highlighting its expertise, authority, and trustworthiness in delivering exceptional products.

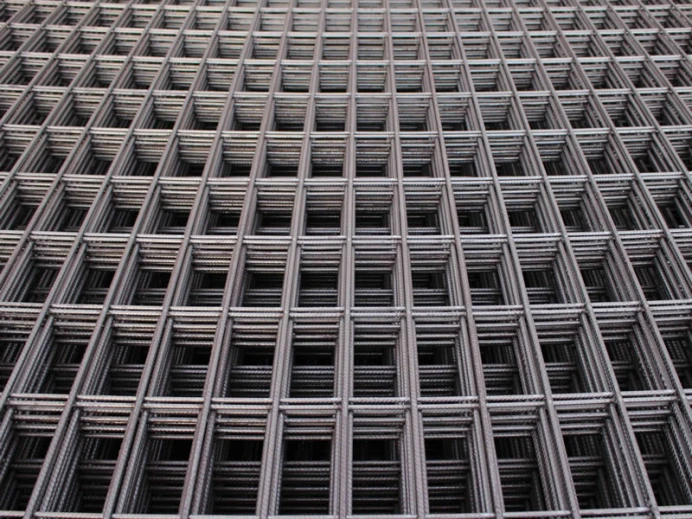

Inside a thriving wire mesh factory, the heartbeat is its advanced machinery, capable of crafting an array of mesh types—welded, woven, and expanded. Each type bears its significance, tailored meticulously to meet diverse industrial demands. Welded wire mesh, for instance, is prized in construction for its robustness, ensuring stable structures. In parallel, woven wire mesh's flexibility finds use in filtration systems, where precision is paramount. The expertise in selecting and utilizing the right equipment marks the factory's strength, reflecting a deep understanding of diverse client needs.

Employee expertise elevates a wire mesh factory’s reputation from a mere manufacturing hub to an industry leader. Skilled craftsmen with years of experience drive production with precision and insight. Their proficiency not only ensures product quality but fosters innovation. It is within this crucible of skill that the factory can cater to custom demands, whether that is creating intricate mesh patterns for architectural marvels or designing high-tensile meshes for resilient infrastructure projects. This expertise is fortified by ongoing training, keeping personnel abreast of technological advancements and quality practices.

Gaining authority in the wire mesh industry requires a commitment to both quality and service. This factory’s journey to authority status involves rigorous quality control systems that include strength testing, corrosion analysis, and dimensional verification. An authoritative wire mesh factory not only meets internationally recognized standards, such as ISO certifications, but often exceeds them, setting benchmarks for others. This adherence to quality protocols reassures clients of the product's reliability, thus enhancing the factory’s reputation on a global scale.

Trustworthiness is built through transparency and client-centric approaches. A reputable wire mesh factory maintains clear communication channels, ensuring clients are informed at every stage of the production process. Customization options are discussed in detail, with honesty regarding capabilities and timeframes. An informative online presence further cements trust—comprehensive websites offering insight into the production process, product specifications, and client testimonials serve as pivotal tools in the digital age.

In conclusion, the essence of an exemplary wire mesh factory lies in its holistic commitment to product excellence, grounded in a foundation of expertise, authority, and trust. The products emerging from such factories are not just functional elements; they are solutions derived from a blend of skilled craftsmanship, innovative engineering, and an uncompromising stance on quality. As industries lean increasingly towards specialized requirements and sustainable solutions, the factories’ role transcends mere production to become partners in progress, shaping a future where reliability is woven into the very fabric of industrial development.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.