Jan . 09, 2025 14:09 Back to list

wire mesh factory

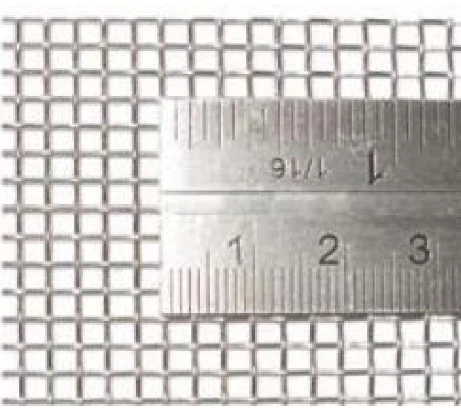

Wire mesh factories have become pivotal players in the industrial sector, providing an extensive range of products that cater to diverse applications. To truly harness the potential of these products, it is essential to understand the production process, the expertise involved, and the myriad applications they support.

Authoritativeness is a hallmark of a reputable wire mesh factory. These factories often possess certifications from recognized industry bodies, demonstrating compliance with international standards. Certifications such as ISO 9001 ensure that factories maintain a high level of quality management, which translates into superior products. Furthermore, factories engage in continuous improvement practices, adopting the latest manufacturing technologies and adhering to environmentally sustainable processes. This commitment not only enhances product quality but also establishes the factory’s authority in the wire mesh market. Trustworthiness of a wire mesh factory is built on transparent business practices and customer-centric approaches. Trust is fortified by offering warranties on products, ensuring consumers are confident in their purchases. Additionally, reliable logistics and supply chain management play a crucial role in meeting delivery timelines and maintaining product integrity during transport. Customer feedback and reviews serve as testament to a factory’s credibility, often reflecting the factory’s dedication to addressing customer inquiries and solving any issues promptly. In the dynamic landscape of industrial manufacturing, a wire mesh factory embodies a confluence of technology, expertise, authority, and trust. These factories are not just producers; they are innovators driving industries forward. By consistently delivering high-quality and tailored mesh solutions, wire mesh factories secure their position as indispensable partners in industrial advancement. As global demand for wire mesh products continues to grow, these factories will remain at the forefront, leading the charge toward a more interconnected and industrially robust future.

Authoritativeness is a hallmark of a reputable wire mesh factory. These factories often possess certifications from recognized industry bodies, demonstrating compliance with international standards. Certifications such as ISO 9001 ensure that factories maintain a high level of quality management, which translates into superior products. Furthermore, factories engage in continuous improvement practices, adopting the latest manufacturing technologies and adhering to environmentally sustainable processes. This commitment not only enhances product quality but also establishes the factory’s authority in the wire mesh market. Trustworthiness of a wire mesh factory is built on transparent business practices and customer-centric approaches. Trust is fortified by offering warranties on products, ensuring consumers are confident in their purchases. Additionally, reliable logistics and supply chain management play a crucial role in meeting delivery timelines and maintaining product integrity during transport. Customer feedback and reviews serve as testament to a factory’s credibility, often reflecting the factory’s dedication to addressing customer inquiries and solving any issues promptly. In the dynamic landscape of industrial manufacturing, a wire mesh factory embodies a confluence of technology, expertise, authority, and trust. These factories are not just producers; they are innovators driving industries forward. By consistently delivering high-quality and tailored mesh solutions, wire mesh factories secure their position as indispensable partners in industrial advancement. As global demand for wire mesh products continues to grow, these factories will remain at the forefront, leading the charge toward a more interconnected and industrially robust future.

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.