Feb . 18, 2025 12:05 Back to list

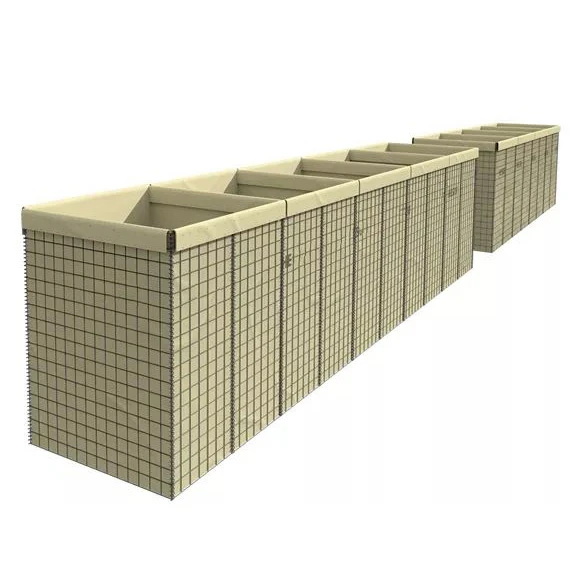

Pvc Coated Welded Wire Mesh Rolls

Wire mesh for concrete slabs serves as an essential component in the construction industry due to its ability to enhance the strength and durability of concrete works. Ensuring that the structural integrity of a concrete slab is maintained, wire mesh is specifically designed to prevent cracking and improving load distribution. As construction methodologies evolve, understanding the nuances and advantages of utilizing wire mesh becomes indispensable for professionals aiming to deliver robust and long-lasting results.

Furthermore, wire mesh contributes to the construction process’s efficiency and cost-effectiveness. By utilizing this material, projects often require less concrete to achieve the same strength, thus reducing material costs. Moreover, the ease of installation compared to rebar can lead to shorter construction timelines and decreased labor expenses. This financial advantage does not compromise on performance, as wire mesh still offers substantial structural support and longevity. The expertise associated with wire mesh application also encompasses the environmental considerations of modern construction. As sustainability becomes a prevailing factor in project planning, the recyclability of wire mesh and its ability to reduce material waste align with eco-friendly initiatives. Utilizing wire mesh not only supports structural integrity but does so within a framework that respects contemporary sustainability goals. In summary, wire mesh for concrete slabs stands as a pivotal element in modern construction, offering enhanced crack resistance, structural support, and cost savings. Through expert application and careful planning, this material ensures the durability and safety of concrete projects. As construction continues to advance, reliance on such tried and true methods reaffirms the expertise and authority the industry places in wire mesh, justifying its ongoing selection in a wide range of building projects.

Furthermore, wire mesh contributes to the construction process’s efficiency and cost-effectiveness. By utilizing this material, projects often require less concrete to achieve the same strength, thus reducing material costs. Moreover, the ease of installation compared to rebar can lead to shorter construction timelines and decreased labor expenses. This financial advantage does not compromise on performance, as wire mesh still offers substantial structural support and longevity. The expertise associated with wire mesh application also encompasses the environmental considerations of modern construction. As sustainability becomes a prevailing factor in project planning, the recyclability of wire mesh and its ability to reduce material waste align with eco-friendly initiatives. Utilizing wire mesh not only supports structural integrity but does so within a framework that respects contemporary sustainability goals. In summary, wire mesh for concrete slabs stands as a pivotal element in modern construction, offering enhanced crack resistance, structural support, and cost savings. Through expert application and careful planning, this material ensures the durability and safety of concrete projects. As construction continues to advance, reliance on such tried and true methods reaffirms the expertise and authority the industry places in wire mesh, justifying its ongoing selection in a wide range of building projects.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.