Jan . 09, 2025 10:50 Back to list

buy irregular blue quartz

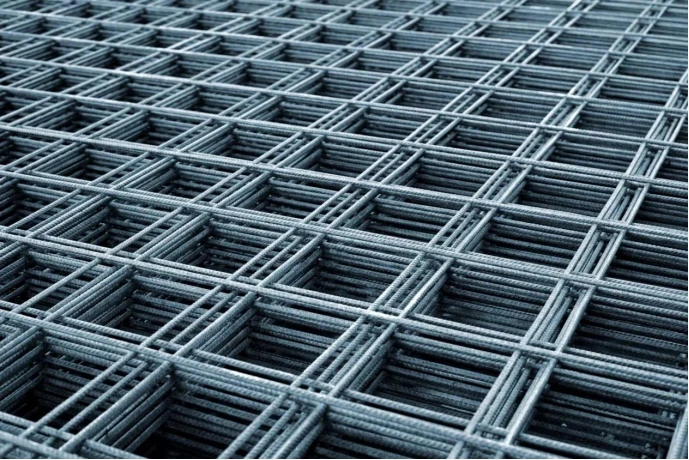

In the intricate world of construction and industrial applications, wire mesh stands out as a highly versatile material, serving countless purposes across various sectors. When selecting a wire mesh manufacturer, numerous factors come into play, each pivotal to ensure you receive a quality product tailored to your specific needs.

Authoritativeness in this field is established not only through the breadth of product offerings but also through active engagement in industry standards and certifications. Leading wire mesh manufacturers frequently align with international quality benchmarks, acquiring certifications that validate their products’ adherence to global safety and quality standards. Moreover, these manufacturers often contribute to industry knowledge pools by participating in trade fairs, publishing technical articles, and offering training workshops, fostering trust within the market ecosystem. Trustworthiness is further built through transparent business practices. A reliable wire mesh manufacturer will maintain open communication channels, ensuring that clients receive comprehensive guidance and support throughout the purchase and post-purchase phases. This includes facilitating detailed consultations to understand client needs, accommodating custom orders, and offering post-installation support to address any concerns that may arise. In summary, choosing a wire mesh manufacturer goes beyond seeking a supplier; it involves partnering with an entity with proven capabilities to deliver high-quality, reliable, and suitably customized products. Their experience, bolstered by a robust quality management system, expert knowledge of industry requirements, and commitment to maintaining authoritative standards, makes them a pivotal ally in any project requiring wire mesh solutions. Trust is cultivated through transparent operations, genuine customer support, and a steadfast commitment to upholding the highest quality and safety standards. Through these collaborative efforts, manufacturers ensure that their wire mesh products not only meet but often exceed the expectations and demands of modern industry applications.

Authoritativeness in this field is established not only through the breadth of product offerings but also through active engagement in industry standards and certifications. Leading wire mesh manufacturers frequently align with international quality benchmarks, acquiring certifications that validate their products’ adherence to global safety and quality standards. Moreover, these manufacturers often contribute to industry knowledge pools by participating in trade fairs, publishing technical articles, and offering training workshops, fostering trust within the market ecosystem. Trustworthiness is further built through transparent business practices. A reliable wire mesh manufacturer will maintain open communication channels, ensuring that clients receive comprehensive guidance and support throughout the purchase and post-purchase phases. This includes facilitating detailed consultations to understand client needs, accommodating custom orders, and offering post-installation support to address any concerns that may arise. In summary, choosing a wire mesh manufacturer goes beyond seeking a supplier; it involves partnering with an entity with proven capabilities to deliver high-quality, reliable, and suitably customized products. Their experience, bolstered by a robust quality management system, expert knowledge of industry requirements, and commitment to maintaining authoritative standards, makes them a pivotal ally in any project requiring wire mesh solutions. Trust is cultivated through transparent operations, genuine customer support, and a steadfast commitment to upholding the highest quality and safety standards. Through these collaborative efforts, manufacturers ensure that their wire mesh products not only meet but often exceed the expectations and demands of modern industry applications.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.