Jan . 09, 2025 11:50 Back to list

popular exterior decoration natural stacked stone panel

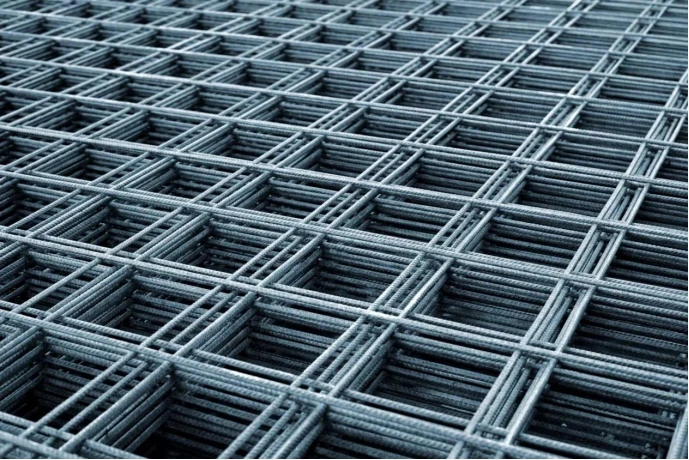

Navigating the expansive world of wire mesh requires insight, expertise, and a commitment to quality. Wire mesh manufacturers occupy a pivotal role in various industries, providing solutions that are integral to constructing durable, efficient, and innovative applications. These manufacturers are not only producers but are also custodians of quality, ensuring each mesh meets the rigorous demands of their diverse clientele.

Authority in the wire mesh manufacturing landscape is often established through certifications and compliance with international standards. Manufacturers adhere to ISO certifications, which reflect a commitment to quality management and continuous improvement practices. Such credentials provide reassurance to clients that the products they are investing in meet global standards for reliability and safety. Authority is further cemented when manufacturers contribute to regulatory standards, showcasing their role not only as participants but as leaders driving industry protocols. Trustworthiness stands on the foundational values of transparency, integrity, and accountability. Wire mesh manufacturers that engage openly with their clients, providing clear communication and honest timelines, foster strong business relationships. They often offer extended warranties and comprehensive after-sales services, demonstrating confidence in their products and a commitment to client satisfaction. By using sustainable materials and practices, they also convey a concern for ethical manufacturing and environmental stewardship, which is increasingly important to consumers. Ultimately, successful wire mesh manufacturers combine technical expertise with customer-focused service. By nurturing a culture of continuous improvement and client engagement, they remain indispensable to industries reliant on their specialized products. Their dedication to quality and innovation not only drives their success but also supports the advancement of their clients' objectives, ensuring mutual growth and prosperity. As market requirements evolve, these manufacturers persist as beacons of reliability, adapting and expanding to meet and exceed the expectations of a diverse, global clientele.

Authority in the wire mesh manufacturing landscape is often established through certifications and compliance with international standards. Manufacturers adhere to ISO certifications, which reflect a commitment to quality management and continuous improvement practices. Such credentials provide reassurance to clients that the products they are investing in meet global standards for reliability and safety. Authority is further cemented when manufacturers contribute to regulatory standards, showcasing their role not only as participants but as leaders driving industry protocols. Trustworthiness stands on the foundational values of transparency, integrity, and accountability. Wire mesh manufacturers that engage openly with their clients, providing clear communication and honest timelines, foster strong business relationships. They often offer extended warranties and comprehensive after-sales services, demonstrating confidence in their products and a commitment to client satisfaction. By using sustainable materials and practices, they also convey a concern for ethical manufacturing and environmental stewardship, which is increasingly important to consumers. Ultimately, successful wire mesh manufacturers combine technical expertise with customer-focused service. By nurturing a culture of continuous improvement and client engagement, they remain indispensable to industries reliant on their specialized products. Their dedication to quality and innovation not only drives their success but also supports the advancement of their clients' objectives, ensuring mutual growth and prosperity. As market requirements evolve, these manufacturers persist as beacons of reliability, adapting and expanding to meet and exceed the expectations of a diverse, global clientele.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.