Dec . 11, 2024 09:04 Back to list

Woven Wire Mesh for Enhanced Concrete Strength and Durability Reinforcement Solutions

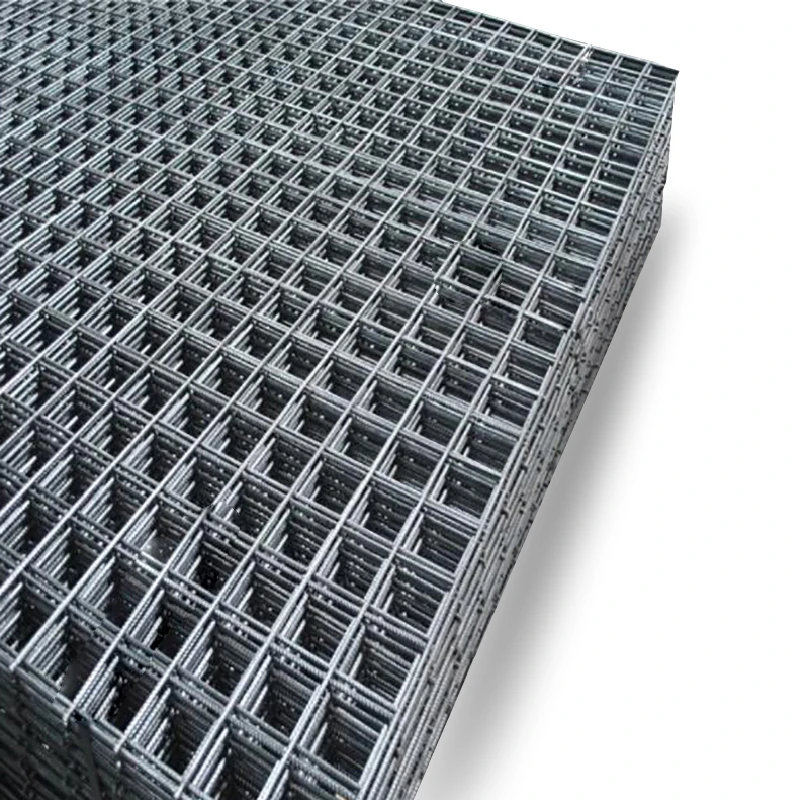

Woven Wire Mesh Concrete Reinforcement A Comprehensive Overview

Concrete is one of the most widely used construction materials in the world, known for its strength, durability, and versatility. However, its inherent brittleness can be a limitation in certain applications, particularly under tensile stress. To enhance the performance of concrete structures, various reinforcement techniques have been developed, among which woven wire mesh is a prominent solution. This article explores the characteristics, advantages, applications, and installation practices of woven wire mesh concrete reinforcement.

What is Woven Wire Mesh?

Woven wire mesh is a type of steel reinforcement made by interlacing strands of wire to create a grid-like structure. The wires are usually available in various gauges and can be made from different materials, though steel is the most common due to its excellent tensile strength and bonding properties with concrete. The mesh can have variable openings, thicknesses, and configurations, depending on the specific requirements of a given project.

Advantages of Woven Wire Mesh

1. Enhanced Tensile Strength One of the main benefits of using woven wire mesh in concrete is the enhancement of tensile strength. Concrete is strong in compression but weak in tension. The addition of woven wire mesh helps to distribute tensile forces more evenly throughout the concrete, reducing the likelihood of cracking under stress.

2. Improved Crack Control By reinforcing concrete with woven wire mesh, the potential for random cracking is significantly reduced. This is particularly important in large slabs, pavements, and structures that are subject to temperature changes and load variations.

3. Cost-Effective Solution Compared to traditional rebar reinforcement, woven wire mesh can be more economical in certain applications. It is often more lightweight and easier to handle, which can reduce labor costs and simplify installation processes.

4. Facilitates Precise Engineering Woven wire mesh is manufactured under controlled conditions, ensuring uniformity and quality. This precision allows engineers and architects to design structures with better predictability regarding structural behavior and load response.

5. Environmentally Friendly Steel is recyclable, making woven wire mesh a more sustainable option in construction. Its durability extends the lifespan of concrete structures, thereby reducing the need for frequent repairs or replacements.

Applications of Woven Wire Mesh

Woven wire mesh is used across various construction applications, including

woven wire mesh concrete reinforcement

- Pavements and Floors It is commonly used to reinforce concrete slabs, pavements, and flooring systems, reducing the risk of crack formation and ensuring the durability of surfaces subjected to foot and vehicle traffic.

- Walls and Siding In precast concrete elements and masonry walls, woven wire mesh provides necessary lateral restraint and enhances the overall structural integrity.

- Retaining Walls The use of mesh in retaining wall construction helps manage soil pressure and reinforces the wall material, improving stability, especially under dynamic loads.

- Industrial Applications Many industrial facilities and warehouses utilize woven wire mesh for flooring and storage systems, where heavy loads are anticipated.

Installation Practices

Proper installation of woven wire mesh is critical to ensure its effectiveness in reinforcing concrete. Here are some essential steps for installation

1. Surface Preparation The concrete surface should be clean and free of debris to ensure proper bonding with the mesh.

2. Placement The mesh should be placed at the correct elevation within the concrete section, typically one-third to one-half of the depth of the slab, to maximize its tensile capabilities.

3. Concrete Pouring Care should be taken during the pouring process to avoid displacing the mesh. Proper vibration techniques can help ensure that the concrete envelops the mesh uniformly.

4. Curing Once poured, the concrete must be adequately cured to prevent cracking. Curing retains moisture and aids in the hydration of cement, subsequently enhancing the strength of the concrete.

Conclusion

Woven wire mesh concrete reinforcement offers a versatile, cost-effective, and efficient solution for enhancing the structural performance of concrete. As the construction industry continues to evolve with a focus on sustainability and durability, the utilization of woven wire mesh is expected to gain further traction. By understanding its benefits and implementing best practices for installation, engineers and construction professionals can significantly improve the longevity and safety of concrete structures.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.