Feb . 10, 2025 10:10 Back to list

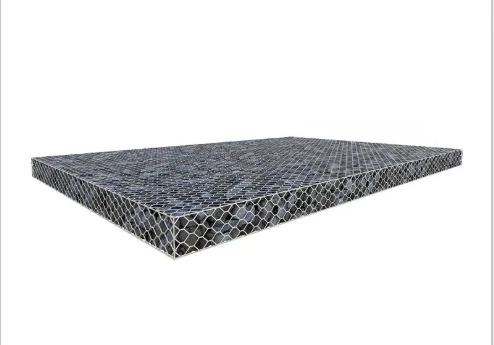

irregular black limestone

When considering solutions for security, construction, or various industrial applications, 1 x 1 welded wire mesh often emerges as a pivotal element. Its popularity is attributed not just to its durability and strength, but also its versatility in a wide range of projects. Digging deeper into the pricing dynamics of this indispensable material reveals the intrinsic factors that influence its cost, as well as offering practical insights for potential buyers.

Geographical location also subtly affects pricing. Local manufacturing typically results in lower transportation costs and shorter delivery times, making it a cost-efficient choice for projects within proximity. Conversely, importing wire mesh from a distant supplier might attract additional logistical fees, elevating the overall cost. Therefore, evaluating local market options could potentially offer both financial savings and support for local industry. Purchasing volume is yet another element impacting the price. Bulk purchases often qualify for discounts, reducing the cost per unit significantly. For large-scale projects, buying in bulk not only optimizes expenses but also ensures consistency in material quality and appearance throughout the project. While smaller quantities may offer flexibility, they typically come at a higher cost per square foot or meter. Engaging with reputable suppliers and manufacturers can provide added benefits beyond mere pricing considerations. Established suppliers often provide a wealth of knowledge and guidance about the most suitable products for specific applications. Their extensive experience ensures they recommend products that align perfectly with project needs, thereby maximizing both financial and functional outcomes. Additionally, such suppliers often uphold transparent pricing policies, enhancing trust and fostering long-term business relationships. Moreover, understanding market conditions can be advantageous in making cost-effective decisions. Seasonal fluctuations in raw material costs or changes in tariff policies might impact pricing structures. Staying informed about these variations allows buyers to time their purchases strategically, potentially avoiding periods of inflated costs. In conclusion, the pricing of 1 x 1 welded wire mesh is influenced by a myriad of factors, from material quality and production processes to customization and market conditions. As a potential buyer, comprehending these dynamics not only aids in budgeting but also in selecting the most suitable product that meets both your financial and functional requirements. Considering long-term benefits over immediate costs, engaging with reliable suppliers, and maintaining awareness of market trends collectively contribute to a sound purchasing decision. With a strategic approach backed by informed choices, acquiring welded wire mesh becomes not just a transaction but a foundation for enduring success in any project.

Geographical location also subtly affects pricing. Local manufacturing typically results in lower transportation costs and shorter delivery times, making it a cost-efficient choice for projects within proximity. Conversely, importing wire mesh from a distant supplier might attract additional logistical fees, elevating the overall cost. Therefore, evaluating local market options could potentially offer both financial savings and support for local industry. Purchasing volume is yet another element impacting the price. Bulk purchases often qualify for discounts, reducing the cost per unit significantly. For large-scale projects, buying in bulk not only optimizes expenses but also ensures consistency in material quality and appearance throughout the project. While smaller quantities may offer flexibility, they typically come at a higher cost per square foot or meter. Engaging with reputable suppliers and manufacturers can provide added benefits beyond mere pricing considerations. Established suppliers often provide a wealth of knowledge and guidance about the most suitable products for specific applications. Their extensive experience ensures they recommend products that align perfectly with project needs, thereby maximizing both financial and functional outcomes. Additionally, such suppliers often uphold transparent pricing policies, enhancing trust and fostering long-term business relationships. Moreover, understanding market conditions can be advantageous in making cost-effective decisions. Seasonal fluctuations in raw material costs or changes in tariff policies might impact pricing structures. Staying informed about these variations allows buyers to time their purchases strategically, potentially avoiding periods of inflated costs. In conclusion, the pricing of 1 x 1 welded wire mesh is influenced by a myriad of factors, from material quality and production processes to customization and market conditions. As a potential buyer, comprehending these dynamics not only aids in budgeting but also in selecting the most suitable product that meets both your financial and functional requirements. Considering long-term benefits over immediate costs, engaging with reliable suppliers, and maintaining awareness of market trends collectively contribute to a sound purchasing decision. With a strategic approach backed by informed choices, acquiring welded wire mesh becomes not just a transaction but a foundation for enduring success in any project.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.