Feb . 04, 2025 01:27 Back to list

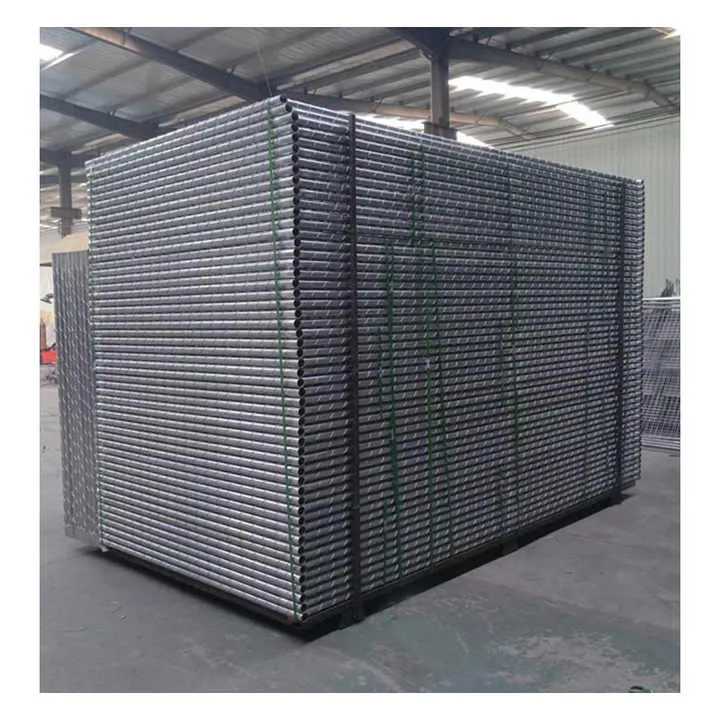

heavy duty welded wire mesh

Heavy duty welded wire mesh stands as a robust and versatile solution across numerous industries, celebrated for its strength, durability, and wide range of applications. When considering the adoption of heavy duty welded wire mesh, it’s essential to understand the product's characteristics, technical specifications, and potential uses to make informed decisions that maximize value while ensuring safety and efficacy.

For marine environments, utilizing stainless steel heavy duty welded wire mesh is an intelligent choice due to its exceptional resistance to corrosion. Port facilities, shipping yards, and coastal engineering projects rely on this material to maintain infrastructure integrity in saline conditions, reducing maintenance costs and prolonging the lifespan of the installations. From a specification standpoint, choosing the right gauge and aperture size is critical. Thicker gauges contribute to greater tensile strength, while varying aperture sizes can be selected depending on the application—small apertures for increased security, or larger ones for less restricted visibility. It is imperative to consult with an expert to determine the ideal configuration that aligns with the project needs and environmental conditions. Incorporating heavy duty welded wire mesh into projects not only requires an understanding of its material and structural benefits but also a commitment to quality sourcing and proper installation. Partnering with reputable manufacturers and suppliers ensures access to premium-grade products that comply with industry standards and regulations, enhancing performance and safety outcomes. Ultimately, the robust nature and adaptable applications of heavy duty welded wire mesh make it a preferred material for industry professionals seeking reliability and longevity. Its advanced design ensures that it can meet the most demanding of requirements, standing as a testament to modern engineering capabilities where strength, durability, and versatility converge.

For marine environments, utilizing stainless steel heavy duty welded wire mesh is an intelligent choice due to its exceptional resistance to corrosion. Port facilities, shipping yards, and coastal engineering projects rely on this material to maintain infrastructure integrity in saline conditions, reducing maintenance costs and prolonging the lifespan of the installations. From a specification standpoint, choosing the right gauge and aperture size is critical. Thicker gauges contribute to greater tensile strength, while varying aperture sizes can be selected depending on the application—small apertures for increased security, or larger ones for less restricted visibility. It is imperative to consult with an expert to determine the ideal configuration that aligns with the project needs and environmental conditions. Incorporating heavy duty welded wire mesh into projects not only requires an understanding of its material and structural benefits but also a commitment to quality sourcing and proper installation. Partnering with reputable manufacturers and suppliers ensures access to premium-grade products that comply with industry standards and regulations, enhancing performance and safety outcomes. Ultimately, the robust nature and adaptable applications of heavy duty welded wire mesh make it a preferred material for industry professionals seeking reliability and longevity. Its advanced design ensures that it can meet the most demanding of requirements, standing as a testament to modern engineering capabilities where strength, durability, and versatility converge.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.