Feb . 04, 2025 01:50 Back to list

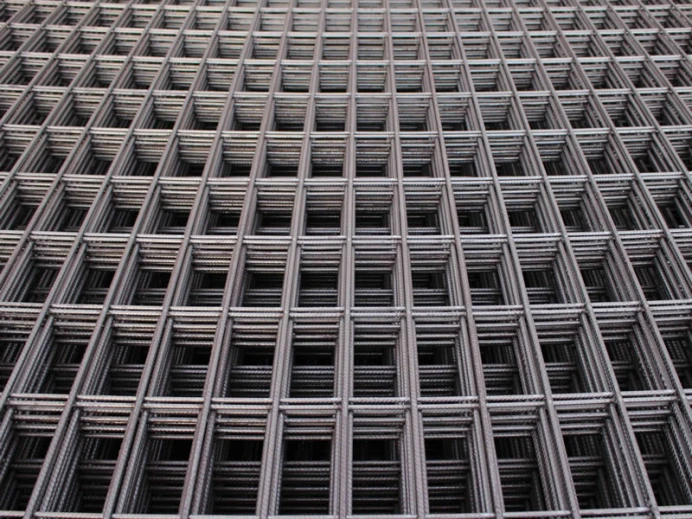

wire reinforcement

Wire reinforcement stands as a pivotal element in modern construction, offering unparalleled structural integrity and longevity to an array of projects. This innovative product has transformed the way we think of reinforcing structures, drawing from decades of engineering expertise and real-world application to deliver strength and sustainability.

Authoritativeness in the domain of wire reinforcement is demonstrated through adherence to industry standards and continuous innovations. Manufacturers and engineers consistently engage in extensive research and testing to ensure products not only meet but exceed regulatory requirements. Organizations such as the American Concrete Institute and the International Organization for Standardization have set guidelines that govern the dimensions, tensile strength, and chemical composition of wire used in reinforcement. By aligning with these standards, companies affirm their commitment to delivering materials that uphold structural integrity and safety. Trustworthiness in selecting wire reinforcement materials cannot be overstated. Engineers and contractors look for suppliers with proven track records and a reputation for quality. Transparency in production processes, comprehensive warranty policies, and robust customer support services are key factors in building trust. By fostering open communication with clients and staying receptive to feedback, wire reinforcement providers can ensure their products are reliably used in constructing safe and durable structures. An example of a successful wire reinforcement application is evident in the Burj Khalifa, the world's tallest building. Engineers employed advanced reinforcement techniques that included specially designed steel wire mesh to withstand the immense pressures and dynamic loads imposed upon such a towering structure. This not only secured the building’s structural viability but also set a benchmark in high-rise construction practices. In summation, wire reinforcement is more than just a construction staple; it is a fundamental component that bridges the gap between architectural vision and practical reality. Through its integration of engineering expertise, adherence to authoritative standards, and achievement of long-term performance, wire reinforcement continues to be an invaluable asset in constructing the world's most demanding projects. With continued innovation and a steadfast commitment to quality, it will remain at the forefront of construction excellence for years to come.

Authoritativeness in the domain of wire reinforcement is demonstrated through adherence to industry standards and continuous innovations. Manufacturers and engineers consistently engage in extensive research and testing to ensure products not only meet but exceed regulatory requirements. Organizations such as the American Concrete Institute and the International Organization for Standardization have set guidelines that govern the dimensions, tensile strength, and chemical composition of wire used in reinforcement. By aligning with these standards, companies affirm their commitment to delivering materials that uphold structural integrity and safety. Trustworthiness in selecting wire reinforcement materials cannot be overstated. Engineers and contractors look for suppliers with proven track records and a reputation for quality. Transparency in production processes, comprehensive warranty policies, and robust customer support services are key factors in building trust. By fostering open communication with clients and staying receptive to feedback, wire reinforcement providers can ensure their products are reliably used in constructing safe and durable structures. An example of a successful wire reinforcement application is evident in the Burj Khalifa, the world's tallest building. Engineers employed advanced reinforcement techniques that included specially designed steel wire mesh to withstand the immense pressures and dynamic loads imposed upon such a towering structure. This not only secured the building’s structural viability but also set a benchmark in high-rise construction practices. In summation, wire reinforcement is more than just a construction staple; it is a fundamental component that bridges the gap between architectural vision and practical reality. Through its integration of engineering expertise, adherence to authoritative standards, and achievement of long-term performance, wire reinforcement continues to be an invaluable asset in constructing the world's most demanding projects. With continued innovation and a steadfast commitment to quality, it will remain at the forefront of construction excellence for years to come.

Perv:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.