Aug . 08, 2025 05:00 Back to list

Premium BRC Mesh: Durable Weld Mesh for Construction

The Indispensable Role of BRC Mesh in Modern Infrastructure and Security

In the rapidly evolving landscape of construction, security, and industrial applications, the demand for robust, reliable, and cost-effective materials is paramount. Among these, brc mesh stands out as a foundational component, offering unparalleled versatility and structural integrity. This comprehensive guide delves into the world of brc mesh, exploring its technical nuances, diverse applications, manufacturing excellence, and the inherent advantages it brings to various sectors. From its foundational role in reinforcing concrete to its ubiquitous presence in advanced perimeter security, understanding brc mesh is crucial for engineers, procurement specialists, and project managers alike.

Current Industry Trends and Market Dynamics for BRC Mesh

The global market for wire mesh products, including brc mesh, is experiencing steady growth, driven by several key factors:

- Infrastructure Development: Massive government investments in infrastructure projects worldwide, particularly in developing nations, fuel the demand for high-quality reinforcing materials like brc weld mesh. Roads, bridges, airports, and urban development projects extensively utilize this material.

- Urbanization and Security Needs: As urban populations expand, so does the need for secure perimeters for residential areas, commercial complexes, and public spaces. The aesthetic appeal and robust security features of products like the BRC Roll Top Fence, which heavily relies on brc mesh, make them preferred choices.

- Technological Advancements: Innovations in steel production and welding technologies enable the creation of stronger, more uniform, and cost-efficient brc mesh products. This includes advancements in galvanization and PVC coating for enhanced durability.

- Sustainability Focus: The push for sustainable construction practices leads to a preference for materials with long lifespans and recyclability. Steel wire mesh brc fits this criterion well, contributing to greener building initiatives.

- Diversification of Applications: Beyond traditional construction, brc mesh finds new applications in agriculture (animal enclosures), mining (rockfall protection), and even artistic installations, broadening its market reach.

Industry reports project a consistent compound annual growth rate (CAGR) for the global wire mesh market, often exceeding 4-5% over the next five to seven years, underscoring the vital role of brc mesh in future development projects.

Understanding Technical Parameters of BRC Mesh

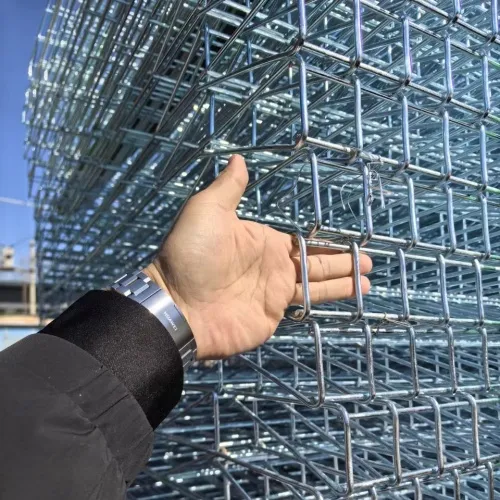

BRC mesh refers to British Reinforced Concrete mesh, a type of welded steel fabric primarily used for concrete reinforcement and fencing. It is manufactured from cold-drawn steel wires, resistance-welded together to form a square or rectangular grid. The precise control over wire diameter, spacing, and weld integrity is crucial for its performance.

Key Technical Specifications and Variants:

- Wire Diameter (d): Typically ranges from 2.5mm to 12mm. Larger diameters indicate greater strength.

- Mesh Aperture (c/c): The spacing between parallel wires, commonly expressed as center-to-center distance. Standard sizes include 50mm x 50mm, 75mm x 75mm, 100mm x 100mm, 150mm x 150mm, 200mm x 200mm, and even larger for specific applications.

- Sheet Dimensions: Standard sheet sizes are common (e.g., 2.4m x 4.8m), but custom sizes are frequently available.

- Material: Primarily low carbon steel, often galvanized (hot-dip or electro-galvanized) or PVC coated for corrosion resistance. High-tensile steel is also used for specific applications requiring superior strength.

- Tensile Strength: A critical property indicating the maximum stress the material can withstand before breaking, typically measured in MPa (Megapascals). For reinforcing mesh, it often adheres to standards like BS 4482 and BS 4483.

- Weld Shear Strength: The strength of the weld points, crucial for maintaining the mesh's structural integrity under load.

Common BRC Mesh Designations and Parameters:

Different regions and applications use specific designations. For instance, a8 brc mesh and a10 brc mesh typically refer to the wire diameter, indicating a mesh made with 8mm and 10mm wires, respectively, often with a specific mesh spacing like 200x200mm. Similarly, brc 3315 mesh is a common reference to a specific type of fabric with defined wire diameters and spacing, often implying a light-duty or medium-duty mesh for various applications like pathways or light concrete slabs. The table below provides a general overview of typical brc mesh specifications:

| Mesh Type/Designation | Wire Diameter (mm) | Mesh Spacing (mm) (Longitudinal x Transverse) | Standard Sheet Size (m) | Typical Application |

|---|---|---|---|---|

| A8 BRC Mesh (e.g., A810) | 8 | 200 x 200 | 2.4 x 4.8 | Slabs, Footings, Foundations, Medium-duty applications |

| A10 BRC Mesh (e.g., A1010) | 10 | 200 x 200 | 2.4 x 4.8 | Heavy-duty slabs, Walls, Concrete roads |

| BRC 3315 Mesh (e.g., C3315/C385) | 3.3 - 3.8 (approx.) | 150 x 150 (common) | 2.4 x 4.8 or 2.0 x 4.0 | Pathways, Light-duty slabs, Patios, Reinforcing masonry |

| Wire Mesh BRC (General) | 2.5 - 12 | 50x50 to 200x200 | Various | General reinforcement, Fencing, Cages |

| BRC Weld Mesh (General) | 2.5 - 12 | Variable based on specific code | Custom/Standard | Reinforcement, Security, Industrial use |

| BRC Roll Top Fence (Product) | 4.0 - 6.0 | 50 x 100, 50 x 150, 50 x 200 | Custom height x 2.5/3.0 | Perimeter Fencing, Security, Public parks |

Product Spotlight: BRC Roll Top Fence - A Premier Application of BRC Mesh

At Bangjun Metal, we specialize in high-quality perimeter solutions, exemplified by our BRC Roll Top Fence. This product leverages the inherent strength and versatility of brc mesh to provide a secure, aesthetically pleasing, and durable fencing solution. The unique 'rolled beam' sections at the top and bottom edges not only enhance the fence's rigidity and strength but also eliminate sharp edges, making it safe for public areas, playgrounds, and residential zones. Visit our product page for more details: https://www.bangjunmetal.com/brc-roll-top-fence.html.

Crafting the Mesh: The Advanced Manufacturing Process of BRC Mesh

The production of high-quality brc mesh is a sophisticated process that demands precision, advanced machinery, and rigorous quality control. It's not just about welding wires; it's about engineering a material that can withstand significant loads and environmental stresses. The typical manufacturing journey involves several critical stages:

1. Wire Rod Sourcing & Drawing

High-grade low carbon steel wire rods are sourced, adhering to international material standards such as ASTM A82 or BS 4482. These rods are then drawn through a series of dies to achieve the precise wire diameter required for the specific brc mesh specification (e.g., for a8 brc mesh or a10 brc mesh).

2. Wire Straightening & Cutting

The drawn wires are automatically straightened to remove any coils or bends. Precision cutting machines then cut the wires to the exact required lengths, ensuring uniformity across the entire mesh sheet. This step is critical for consistent mesh dimensions.

3. Resistance Welding

The heart of brc weld mesh production. Longitudinal and transverse wires are fed into an automatic multi-spot welding machine. This machine uses electric resistance welding to fuse the wires together at each intersection. The process is highly controlled to ensure strong, consistent, and uniform weld points, which are paramount for the mesh's structural integrity and adherence to standards like BS 4483.

4. Quality Inspection & Testing

Post-welding, each sheet of brc mesh undergoes stringent quality checks. This includes visual inspection for defects, dimensional checks (wire diameter, mesh aperture accuracy), and mechanical testing such as weld shear strength tests and tensile strength tests (conforming to ISO/ANSI standards for steel products). This ensures the mesh meets specified load-bearing capacities and durability.

5. Surface Treatment (Optional but Recommended)

For enhanced corrosion resistance, especially for outdoor or harsh environment applications like the BRC Roll Top Fence, the brc mesh panels are subjected to surface treatments. Common methods include:

- Hot-Dip Galvanization: The mesh is immersed in molten zinc, creating a durable, sacrificial coating that offers superior corrosion protection (conforming to BS EN 10244-2 or ASTM A123). This significantly extends the product's lifespan, often exceeding 15-20 years in typical environments.

- Electro-Galvanization: A thinner zinc coating applied via an electrolytic process, offering good initial protection.

- PVC Coating: After galvanization, a layer of PVC (Polyvinyl Chloride) powder is electrostatically applied and then cured, providing an additional barrier against corrosion, UV radiation, and offering a range of color options for aesthetic purposes.

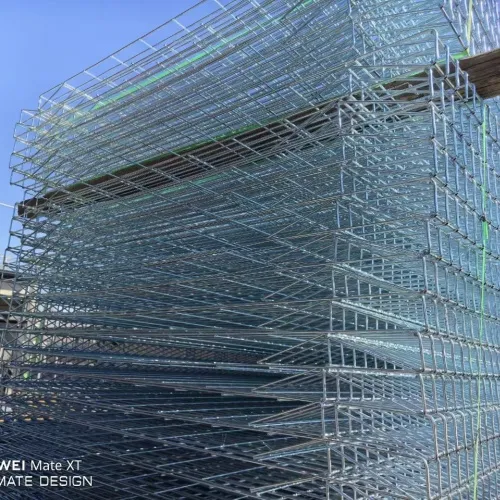

6. Finishing & Packaging

Finally, the treated brc mesh panels are finished (e.g., forming the roll top for BRC Roll Top Fence), bundled, and securely packaged for transport. Proper packaging protects the mesh from damage during transit and storage.

Product Material & Durability

The primary material for our brc mesh and BRC Roll Top Fence products is high-quality low carbon steel wire, selected for its optimal balance of strength and ductility. Coupled with advanced galvanization and PVC coating, our products offer an exceptional service life, typically ranging from 15 to 25 years or more, depending on environmental conditions and maintenance. This extended lifespan significantly reduces the total cost of ownership, providing long-term value for clients.

Testing Standards and Quality Assurance:

Our commitment to quality is unwavering. All our brc mesh products adhere strictly to international testing and manufacturing standards, including but not limited to:

- ISO 9001: For Quality Management Systems, ensuring consistent product quality.

- BS 4483: Specification for steel fabric for the reinforcement of concrete (UK standard).

- BS EN 10244-2: Steel wire and wire products. Non-ferrous metallic coatings on steel wire. Zinc or zinc alloy coatings (European standard for galvanization).

- ASTM A185/A185M: Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete (US standard).

- ASTM A123/A123M: Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products.

These certifications and adherence to rigorous testing protocols underscore our authority and trustworthiness in delivering products that meet and exceed industry benchmarks.

Applicable Industries for BRC Mesh Solutions:

The versatility and resilience of brc mesh make it indispensable across a multitude of industries:

- Civil Construction: Concrete reinforcement in foundations, slabs, roads, bridges, tunnels, and precast elements. Essential for structural integrity.

- Infrastructure: Railway construction, airport perimeters, drainage systems, and water treatment plants (where its anti-corrosion properties are vital).

- Oil & Gas/Petrochemical: Perimeter security for sensitive facilities, equipment enclosures, and structural reinforcement in corrosive environments (where advanced coatings provide crucial protection).

- Metallurgy & Mining: Safety barriers, ventilation shaft mesh, rockfall protection, and material handling systems.

- Water Supply & Drainage: Reinforcement for concrete pipes, channels, and reservoirs; anti-corrosion properties are key to longevity in these applications.

- Security & Fencing: High-security perimeters for commercial, industrial, residential, and public spaces, leveraging products like the BRC Roll Top Fence for enhanced safety and aesthetic appeal.

- Agriculture: Animal enclosures, crop protection, and general farm fencing.

- Utilities: Enclosures for power substations, communication towers, and other critical infrastructure.

In all these applications, the inherent strength and, when treated, the anti-corrosion properties of brc mesh contribute to energy savings by reducing the need for frequent replacements and maintenance, showcasing its long-term cost-effectiveness.

Strategic Application Scenarios for BRC Mesh

The intelligent deployment of brc mesh can significantly enhance project outcomes. Here are specific scenarios:

- Concrete Slab Reinforcement: From ground slabs for warehouses to elevated decks for multi-story buildings, brc mesh provides essential tensile strength, preventing cracks and enhancing load-bearing capacity. For instance, a8 brc mesh or a10 brc mesh are commonly specified for industrial flooring due to their robust properties.

- Roadways and Pavements: Reinforcing concrete pavements with brc weld mesh dramatically increases their durability against heavy traffic loads and temperature fluctuations, extending road life and reducing maintenance costs.

- Precast Concrete Elements: In the manufacturing of precast walls, beams, and culverts, incorporating precisely dimensioned brc mesh ensures consistency and structural integrity, accelerating construction timelines.

- Perimeter Security (BRC Roll Top Fence): For schools, parks, commercial boundaries, and government facilities, the BRC Roll Top Fence offers a highly secure yet unobtrusive barrier. Its rigid structure, formed by robust wire mesh brc, deters unauthorized entry while its smooth top and bottom edges ensure safety, a crucial advantage in public settings.

- Slope Stabilization: In civil engineering projects, brc mesh can be used in conjunction with shotcrete to stabilize slopes and prevent landslides, particularly in challenging terrains.

Technical Advantages of Choosing Quality BRC Mesh

Opting for high-quality brc mesh from a reputable manufacturer offers distinct advantages:

- Superior Strength-to-Weight Ratio: BRC mesh provides significant structural reinforcement with relatively less material compared to traditional rebar configurations, leading to lighter structures without compromising strength.

- Enhanced Crack Control: The uniform distribution of reinforcement across a concrete slab or structure helps to control thermal cracking and shrinkage, improving the overall longevity and appearance of the concrete.

- Cost and Time Efficiency: Pre-welded brc mesh sheets drastically reduce installation time and labor costs on-site compared to tying individual rebar lengths. This directly translates to faster project completion and reduced budget expenditure.

- Consistent Quality: Factory-produced brc weld mesh ensures precise spacing and strong welds, eliminating human error inherent in manual rebar tying and guaranteeing consistent structural performance. This consistency is vital, particularly for high-stakes projects using materials like brc 3315 mesh or heavier gauges like a10 brc mesh.

- Corrosion Resistance: With advanced galvanization and PVC coatings, brc mesh exhibits excellent resistance to rust and degradation, even in harsh environmental conditions (e.g., coastal areas, industrial zones), significantly extending the service life of structures and fencing systems.

Manufacturer Comparison and Bangjun Metal's Commitment

When selecting a supplier for brc mesh, it's essential to consider several factors beyond just price. A truly reliable manufacturer differentiates itself through:

- Raw Material Quality: Insist on suppliers who transparently specify their steel sourcing and adherence to international material standards. Inferior raw materials lead to compromised product performance.

- Manufacturing Precision: Automated welding processes with rigorous quality control, as described in our process section, ensure consistent weld integrity and accurate mesh dimensions.

- Testing and Certification: A manufacturer's adherence to global standards (ISO, ASTM, BS) and willingness to provide test reports are indicators of their commitment to product excellence and reliability.

- Customization Capabilities: The ability to provide tailored solutions (different wire diameters, mesh sizes, coatings) for specific project requirements is a significant advantage.

- Customer Support and After-Sales Service: Responsive communication, clear warranty policies, and technical support are crucial for a smooth project execution.

At Bangjun Metal, we pride ourselves on embodying these qualities. With years of experience in the metal fabrication industry, our expertise in producing premium wire mesh brc products, including the specialized BRC Roll Top Fence, is validated by our numerous successful projects and client testimonials. Our adherence to stringent quality control, from raw material inspection to final product testing, ensures that every piece of brc mesh we supply meets the highest performance criteria. We are dedicated to building long-term partnerships based on trust and mutual success.

Tailored Solutions and Customization for Your BRC Mesh Needs

Recognizing that every project has unique specifications, we offer comprehensive customization options for our brc mesh products. Whether you require specific wire diameters for a heavy-duty industrial floor, non-standard mesh apertures for a specialized architectural application, or custom panel sizes for a unique fencing design like the BRC Roll Top Fence, our engineering team is equipped to provide precise solutions. We work closely with clients to understand their exact requirements, offering CAD drawings, technical consultations, and samples to ensure the final product perfectly aligns with their project's needs. This collaborative approach ensures optimal performance and cost-effectiveness, delivering solutions that are not just standard products, but perfectly engineered components for your success.

Illustrative Application Cases and Client Experience

Our brc mesh products, particularly the BRC Roll Top Fence, have been successfully deployed in a diverse range of projects globally:

- Urban Park Security: For a large municipal park renovation project in Southeast Asia, our BRC Roll Top Fences were chosen for their safety features (no sharp edges) and aesthetic appeal. The galvanized and PVC-coated brc mesh panels have proven resilient against harsh tropical weather, maintaining their integrity and appearance for over five years, reducing maintenance costs significantly.

- Industrial Facility Perimeter: A leading petrochemical plant in the Middle East utilized our heavy-duty brc weld mesh fencing for their entire perimeter. The superior tensile strength and multi-layer corrosion protection were critical for enduring the corrosive desert environment and enhancing site security. Client feedback highlighted the ease of installation and the robust anti-climb features.

- Residential Estate Fencing: In a major housing development project in Australia, our brc mesh fences, specifically designed to meet brc 3315 mesh standards for lighter security, provided attractive and durable boundaries for individual properties. The quick installation process contributed to the project's ahead-of-schedule completion.

- Solar Farm Security: Large-scale solar farms require extensive, durable, and secure fencing. Our a8 brc mesh panels with PVC coating were deployed, providing a robust barrier against trespassers and wildlife, capable of withstanding strong winds and environmental exposure without degrading.

These cases exemplify our practical experience and the versatility of our brc mesh solutions. Our clients consistently report high satisfaction with the durability, ease of installation, and long-term performance of our products, reinforcing our trustworthiness as a leading supplier.

FAQ: Frequently Asked Questions about BRC Mesh and BRC Roll Top Fence

Q1: What is the primary difference between BRC mesh and traditional rebar for concrete reinforcement?

A1: While both are used for concrete reinforcement, brc mesh (welded wire fabric) offers superior control over steel placement, consistent spacing, and significantly faster installation. It minimizes on-site labor for tying individual bars, leading to cost and time efficiencies. It is pre-fabricated, ensuring higher quality control over weld points and material properties than manual rebar tying.

Q2: How does the galvanization process enhance the lifespan of BRC mesh products?

A2: Hot-dip galvanization applies a protective zinc coating to the steel wire. This zinc acts as a sacrificial anode, corroding before the underlying steel. This barrier protection significantly extends the lifespan of the brc mesh, especially in corrosive environments, far beyond that of untreated steel. PVC coating further enhances this protection against environmental elements and UV radiation.

Q3: What are the typical applications of A8 BRC mesh and A10 BRC mesh?

A3: A8 brc mesh and a10 brc mesh refer to specific types of reinforcing mesh with 8mm and 10mm wire diameters, respectively, typically with 200mm x 200mm spacing. They are widely used for concrete slab reinforcement in heavy-duty applications like industrial flooring, multi-story building slabs, roadways, and foundations where significant load-bearing capacity is required.

Q4: Can the BRC Roll Top Fence be customized for specific height or color requirements?

A4: Yes, the BRC Roll Top Fence is highly customizable. We offer a range of standard heights, but also provide custom heights and panel widths to fit unique project dimensions. Furthermore, through our PVC coating process, clients can select from a wide array of RAL colors to match architectural aesthetics or branding requirements.

Q5: What international standards do your BRC mesh products comply with?

A5: Our brc mesh products rigorously comply with major international standards including ISO 9001 (Quality Management), BS 4483 (Steel Fabric for Concrete Reinforcement), BS EN 10244-2 (Zinc Coatings for Steel Wire), and ASTM A185/A185M (Welded Wire Reinforcement for Concrete). This ensures our products meet global benchmarks for quality and performance.

Q6: What is the estimated delivery time for large orders of BRC mesh?

A6: Delivery times for large orders of brc mesh can vary depending on order volume, customization requirements, and current production schedules. Typically, for standard products, lead times range from 2-4 weeks. For highly customized or very large orders, we provide a detailed production and delivery schedule upon order confirmation. We prioritize efficient logistics to ensure timely delivery to your project site.

Q7: Do you offer a warranty on your BRC Roll Top Fence products?

A7: Yes, we stand by the quality of our products. Our BRC Roll Top Fence, benefiting from robust brc mesh construction and advanced coatings, typically comes with a 10-year anti-corrosion warranty for the galvanized and PVC-coated variants under normal environmental conditions. This warranty reflects our confidence in the longevity and performance of our fencing systems. Specific warranty details are provided with each quotation.

Client Support and Trustworthiness

Our dedication extends beyond manufacturing high-quality brc mesh. We provide comprehensive client support from the initial inquiry through to after-sales service. Our team of experts is available for technical consultations, product selection guidance, and problem-solving. We maintain transparent communication regarding order status, delivery schedules, and any potential issues. Our commitment to ISO 9001 certification underscores our structured approach to quality management and customer satisfaction, building strong, trustworthy relationships with our global clientele.

The Future of BRC Mesh: Innovation and Sustainability

The trajectory for brc mesh is one of continued innovation and adaptation. As construction methods become more industrialized, the demand for pre-fabricated, easy-to-install reinforcement solutions will only grow. Advances in steel metallurgy will likely lead to even higher strength-to-weight ratios, further optimizing material usage. Furthermore, the emphasis on sustainability will drive development towards more eco-friendly coatings and increased use of recycled content in steel production, enhancing the environmental profile of wire mesh brc products. Our commitment to continuous improvement means we are actively exploring these innovations to ensure our brc mesh solutions remain at the forefront of the industry.

In summary, brc mesh is far more than just steel wire; it is a meticulously engineered component critical to the safety, durability, and efficiency of modern infrastructure and security systems. From the robust a8 brc mesh used in heavy construction to the elegant yet secure BRC Roll Top Fence enhancing public spaces, its applications are vast and its advantages clear. Choosing a knowledgeable and reliable supplier like Bangjun Metal ensures you receive products that embody expertise, proven experience, unparalleled authoritativeness through adherence to global standards, and the trustworthiness that comes from dedicated customer support and long-term warranties.

References & Further Reading

"The Role of Welded Wire Reinforcement in Concrete Structures." Concrete Construction Magazine. This publication frequently discusses the benefits and technical specifications of brc mesh and welded wire fabric in various construction applications. Access via professional construction industry platforms or academic databases.

"Global Wire Mesh Market - Industry Trends and Forecasts." Market research reports by leading firms like Mordor Intelligence or Grand View Research provide in-depth analysis of the market drivers, segments, and growth projections for the brc mesh sector. Example: Mordor Intelligence - Welded Wire Mesh Market (Note: Specific report content may require subscription).

"Steel Reinforcement in Concrete: A Comprehensive Guide." This could refer to various engineering textbooks or online resources dedicated to civil engineering and material science, often detailing the performance characteristics of different steel reinforcements, including brc weld mesh. An example resource could be provided by organizations like American Concrete Institute (ACI) publications.

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

products.