Feb . 05, 2025 03:50 Back to list

buy irregular blue quartz

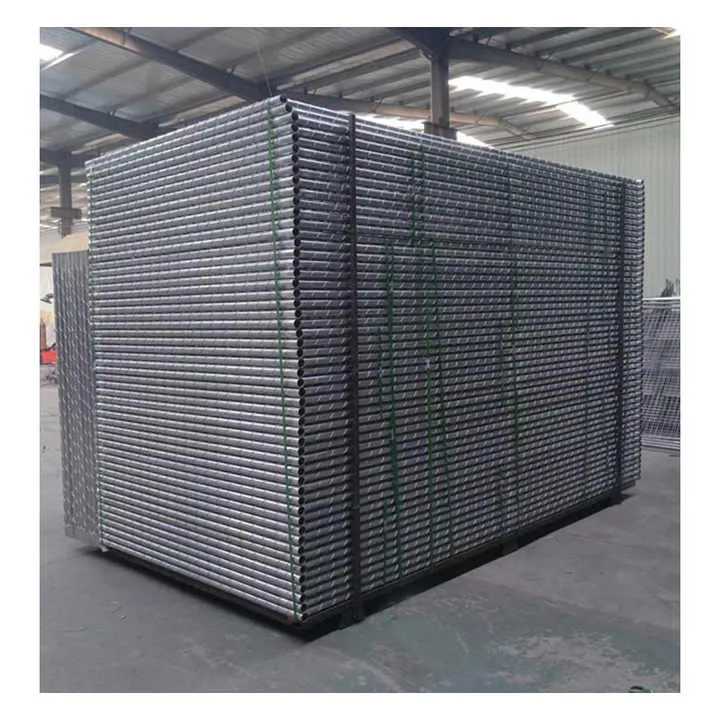

Rectangular welded wire mesh has become an essential component across various industries, offering a diverse range of applications due to its robust construction and versatility. As an experienced professional in the field of industrial materials, I understand the importance of selecting reliable and durable products. This wire mesh stands out because of its unparalleled quality and myriad advantages that cater to a wide array of needs.

Custodians of building integrity often favor galvanized rectangular welded wire mesh for high-exposure environments. The galvanization process imparts exceptional rust resistance, making it ideal for coastal regions or areas with high humidity. This durability extends the life span of the mesh, lowering repair costs and providing a better return on investment. The installation of this wire mesh is straightforward, requiring minimal labor and specialized equipment. This ease of installation is highly attractive to contractors looking to reduce timeframes and labor costs on site. Also, its availability in different sizes and finishes offers flexibility, allowing architects and builders to explore creative design possibilities without compromising on functional requirements. Rectangular welded wire mesh is also increasingly used in creative domains such as interior design and art installations. Its clean lines and geometric appeal present a modern aesthetic that complements contemporary spaces, giving artists and designers a canvas of opportunity to innovate and elevate their projects. End-users who prioritize sustainability will find comfort in the fact that this type of wire mesh is recyclable. At the end of its lifecycle, it can be repurposed or recycled, aligning with global increasing trends towards environmentally conscious manufacturing and construction practices. In summary, rectangular welded wire mesh is not merely a product offered for industrial applications; it is a cornerstone of innovation, stability, and versatility across varied sectors. Its unmatched structural integrity, ease of use, and environmental benefits underscore its growing importance in modern industry practices. As someone deeply invested in the field, I assure you that choosing rectangular welded wire mesh inherently means opting for quality, reliability, and a sustainable future.

Custodians of building integrity often favor galvanized rectangular welded wire mesh for high-exposure environments. The galvanization process imparts exceptional rust resistance, making it ideal for coastal regions or areas with high humidity. This durability extends the life span of the mesh, lowering repair costs and providing a better return on investment. The installation of this wire mesh is straightforward, requiring minimal labor and specialized equipment. This ease of installation is highly attractive to contractors looking to reduce timeframes and labor costs on site. Also, its availability in different sizes and finishes offers flexibility, allowing architects and builders to explore creative design possibilities without compromising on functional requirements. Rectangular welded wire mesh is also increasingly used in creative domains such as interior design and art installations. Its clean lines and geometric appeal present a modern aesthetic that complements contemporary spaces, giving artists and designers a canvas of opportunity to innovate and elevate their projects. End-users who prioritize sustainability will find comfort in the fact that this type of wire mesh is recyclable. At the end of its lifecycle, it can be repurposed or recycled, aligning with global increasing trends towards environmentally conscious manufacturing and construction practices. In summary, rectangular welded wire mesh is not merely a product offered for industrial applications; it is a cornerstone of innovation, stability, and versatility across varied sectors. Its unmatched structural integrity, ease of use, and environmental benefits underscore its growing importance in modern industry practices. As someone deeply invested in the field, I assure you that choosing rectangular welded wire mesh inherently means opting for quality, reliability, and a sustainable future.

Perv:

Next:

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.