Feb . 05, 2025 04:16 Back to list

grey limestone cladding

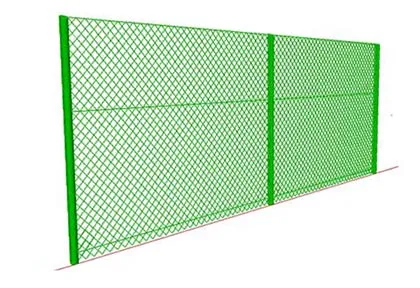

Small welded wire mesh has become an indispensable component in various construction and industrial applications, renowned for its durability and versatility. The manufacturing process of this product involves spot welding wires at each intersection, creating a robust and stable grid. This method ensures the mesh can withstand substantial pressure and provides a long-lasting solution for many structural challenges.

When considering environmental impact, the small welded wire mesh stands out as an eco-friendly option. Its long life cycle reduces the need for frequent replacements, and many manufacturers now offer options made from recycled materials. This aligns well with the growing demand for sustainable building practices and environmentally responsible construction materials. While the technical specifications of small welded wire mesh are vital, the user experience brings additional value. Installation is straightforward, even for those with limited DIY experience. Its lightweight nature means it can be transported and handled with minimal effort, speeding up the completion time of projects. These attributes make it a favorite among both professional installers and DIY enthusiasts. Selecting the right small welded wire mesh involves considering the specific requirements of the project. Professionals advise evaluating where and how the mesh will be used, assessing factors like load-bearing needs, environmental conditions, and potential exposure to corrosive elements. By matching the right specifications to the job, one can optimize both performance and cost-efficiency. Building credibility in the market, manufacturers have earned the trust of their clients by consistently delivering high-quality products and providing comprehensive support services. The key to continuing this trust lies in rigorous testing protocols and adherence to international standards, ensuring each roll of mesh meets the highest industry benchmarks. In conclusion, small welded wire mesh offers an unrivaled blend of strength, versatility, and reliability, establishing itself as a cornerstone material in multiple domains. With its proven performance across various applications, it remains a top choice for professionals seeking to enhance the quality and durability of their projects. Whether for securing an agricultural field, reinforcing concrete structures, or installing industrial partitions, this mesh continues to prove its indispensable value to modern infrastructure development.

When considering environmental impact, the small welded wire mesh stands out as an eco-friendly option. Its long life cycle reduces the need for frequent replacements, and many manufacturers now offer options made from recycled materials. This aligns well with the growing demand for sustainable building practices and environmentally responsible construction materials. While the technical specifications of small welded wire mesh are vital, the user experience brings additional value. Installation is straightforward, even for those with limited DIY experience. Its lightweight nature means it can be transported and handled with minimal effort, speeding up the completion time of projects. These attributes make it a favorite among both professional installers and DIY enthusiasts. Selecting the right small welded wire mesh involves considering the specific requirements of the project. Professionals advise evaluating where and how the mesh will be used, assessing factors like load-bearing needs, environmental conditions, and potential exposure to corrosive elements. By matching the right specifications to the job, one can optimize both performance and cost-efficiency. Building credibility in the market, manufacturers have earned the trust of their clients by consistently delivering high-quality products and providing comprehensive support services. The key to continuing this trust lies in rigorous testing protocols and adherence to international standards, ensuring each roll of mesh meets the highest industry benchmarks. In conclusion, small welded wire mesh offers an unrivaled blend of strength, versatility, and reliability, establishing itself as a cornerstone material in multiple domains. With its proven performance across various applications, it remains a top choice for professionals seeking to enhance the quality and durability of their projects. Whether for securing an agricultural field, reinforcing concrete structures, or installing industrial partitions, this mesh continues to prove its indispensable value to modern infrastructure development.

Latest news

-

Reinforcing Mesh: Core Material of the Construction Industry

NewsJul.07,2025

-

Welded Wire Fabric Reinvented for Modern Projects

NewsJul.04,2025

-

Superiority of Stainless Steel Woven Mesh

NewsJul.04,2025

-

Key Types of Razor Wire and Their Applications

NewsJul.04,2025

-

Durable Metal Fence Types for Security

NewsJul.04,2025

-

Best Materials for Livestock Fence

NewsJul.04,2025

STAY UPDATED

Receive special offers and first look at new

products.

products.